tensile tester for break strength factory

Understanding the Importance of Tensile Testers in Measuring Break Strength

In the realm of material testing, the tensile tester stands out as one of the most crucial tools for assessing the break strength of materials. Whether used in a factory setting or a research environment, understanding how a tensile tester operates and its significance in quality control can greatly impact product reliability and performance.

What is a Tensile Tester?

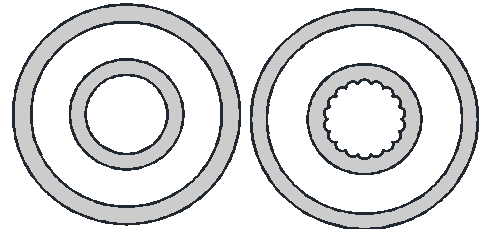

A tensile tester, also known as a tensile strength machine or universal testing machine, is designed to apply a controlled force to a material specimen until it fractures or yields. This device measures various properties, including tensile strength, elongation, and yield strength. These parameters are significant for manufacturers who need to ensure their products meet specific standards and requirements.

Break Strength A Critical Parameter

Break strength refers to the maximum stress or force experienced by a material before it breaks. This property is essential for applications where materials will experience tension, such as ropes, cables, textiles, and structural components. Understanding break strength helps in determining whether a material can withstand operational stresses without failure.

The Testing Process

The tensile testing process is relatively straightforward but requires precision. First, the material sample is prepared and secured in the grips of the tensile tester. The machine then applies a gradual load, typically at a constant rate, to create tension in the material. As the load increases, sensors within the machine record the amount of force exerted and the corresponding elongation of the sample. This data is plotted on a stress-strain curve, which provides invaluable insights into the material's behavior under load.

Once the sample reaches its break point, the tester captures the maximum load applied, which is recorded as the break strength. Furthermore, the elongation before breaking can also be assessed to determine ductility, a crucial factor in material selection for various applications.

tensile tester for break strength factory

Applications Across Industries

Tensile testers are employed across various industries, including construction, manufacturing, textiles, and automotive. In construction, knowing the break strength of materials like steel and concrete ensures infrastructure integrity. In textiles, manufacturers need to understand the strength of fabrics to produce durable clothing and other items. The automotive industry relies heavily on tensile testing to ensure the safety and reliability of components subject to high-stress conditions.

Quality Control and Standards Compliance

Implementing a rigorous tensile testing regime can significantly enhance quality control processes. Many industries are mandated to comply with specific standards, such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). By adhering to these standards, manufacturers ensure that their products are not only reliable but also meet the safety and performance expectations of consumers.

Technological Advancements in Tensile Testing

Recent advancements in technology have transformed tensile testing. Modern tensile testers now feature digital readouts and software integration, allowing for real-time data analysis and reporting. Automation has also streamlined the testing process, reducing human error and increasing throughput. With these innovations, manufacturers can obtain precise and reproducible results faster than ever before.

Conclusion

In summary, tensile testers for break strength measurement are indispensable in today’s manufacturing landscape. As products become increasingly complex and safety standards tighten, the role of effective tensile testing cannot be overstated. By understanding and utilizing tensile testers, manufacturers can ensure their materials meet rigorous standards, thereby optimizing product performance and ensuring customer satisfaction. Investing in high-quality tensile testing equipment, along with skilled personnel to operate these devices, is essential for any factory aiming to maintain a competitive edge in the market. As industries evolve, so too will the methods and technologies surrounding tensile testing, continually enhancing our ability to assess break strength and material integrity.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy