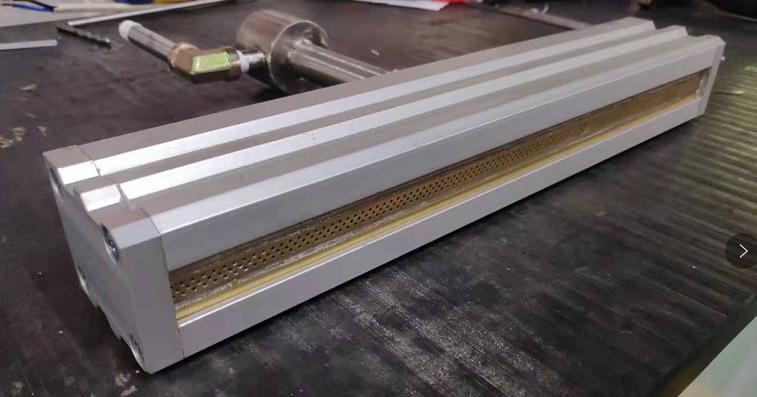

wire fire resistance test machine

Understanding Wire Fire Resistance Test Machines

In today’s rapidly advancing technological landscape, ensuring electrical safety is paramount. One of the key components in this pursuit is the wire fire resistance test machine. This device plays a crucial role in assessing the fire resistance of electrical wires and cables, which are often critical to the functionality and safety of numerous applications ranging from residential buildings to complex industrial systems.

Wire fire resistance test machines are designed to simulate various fire conditions that wires might encounter in real-world scenarios. These machines evaluate how well a wire can withstand exposure to fire and high temperatures without failing or posing additional risks, such as releasing toxic fumes or catching fire itself. The ability to assess these qualities accurately can be the difference between safety and disaster in both commercial and residential settings.

Testing Standards and Protocols

Wire fire resistance testing is governed by various international standards such as the IEC (International Electrotechnical Commission) and UL (Underwriters Laboratories). These organizations establish rigorous testing protocols that manufacturers must adhere to in order to ensure their products meet safety regulations. Test machinery must be calibrated and maintained to conduct accurate assessments under these established standards.

During a typical test, wires are subjected to direct flame exposure or placed in a controlled environment where temperature and smoke levels can be monitored. The results from these tests reveal vital statistics, including the duration the wire can withstand fire without significant degradation or failure. The findings help manufacturers make informed decisions regarding materials and protective coatings that enhance fire resistance.

Features of Wire Fire Resistance Test Machines

wire fire resistance test machine

A modern wire fire resistance test machine includes several key features to enhance accuracy and efficiency. Most machines have a robust temperature control system that allows operators to set specific temperature levels to mirror real-world fire conditions accurately. Advanced sensors are integrated to provide real-time data on temperature changes, smoke generation, and structural integrity of the wire throughout the testing process. This data is invaluable for both regulatory compliance and product development.

In addition, many machines are equipped with automated systems that allow for continuous monitoring and data logging. This automation minimizes human error and maximizes consistency in testing, leading to more reliable results. The data collected can then be used to create detailed reports that not only provide information on the wire’s performance but also enhance the manufacturer’s credibility in the market.

Importance in Electrical Safety

The significance of wire fire resistance testing cannot be overstated. Faulty wiring is a leading cause of electrical fires, which can result in devastating consequences, including property damage, injury, and loss of lives. By utilizing fire resistance test machines, manufacturers can ensure that their products meet essential safety standards before they reach consumers. This proactive approach to safety helps to mitigate risks associated with electrical installations.

Moreover, with the growing demand for renewable energy sources and advancements in materials science, the need for advanced testing methods is more important than ever. As new materials and technologies emerge, wire fire resistance test machines will continue to evolve, adapting to ensure that all electrical installations remain safe under every condition.

Conclusion

Fire resistance testing of wires is a critical aspect of electrical safety, and wire fire resistance test machines are at the forefront of this essential process. With ongoing advancements in testing technology, manufacturers can produce safer, more reliable products. The continuous improvement in fire resistance testing not only protects consumers but also fosters innovation within the electrical industry, ultimately contributing to a safer environment for all.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy