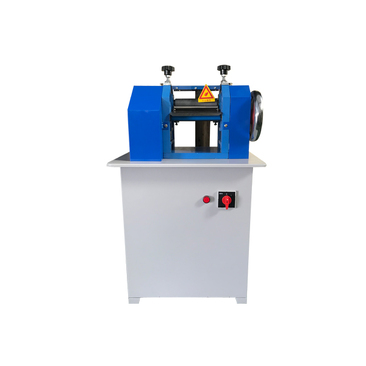

1000 pounds force tensile tester exporter

The Role of 1000 Pounds Force Tensile Testers in Material Testing

In the realm of material science and engineering, tensile testing is a critical procedure used to evaluate the mechanical properties of materials. One of the key instruments employed in this analysis is the tensile tester, specifically those with a capacity of 1000 pounds of force. These machines are essential for providing accurate measurements that help industries assess the strength, elasticity, and ductility of various materials. This article explores the significance of 1000 pounds force tensile testers, their applications, and the growing demand for these machines in the export market.

Understanding Tensile Testing

Tensile testing involves applying a controlled force to a material until it deforms or breaks. This process allows engineers and researchers to observe how materials behave under stress, offering valuable insights into their strength and durability. The tensile tester measures parameters such as yield strength, ultimate tensile strength, and elongation at break, which are pivotal in determining a material's suitability for specific applications.

Why 1000 Pounds Force?

A tensile tester rated at 1000 pounds of force (approximately 4450 Newtons) is particularly versatile for testing a wide range of materials, from plastics and metals to composites and textiles. This capacity strikes a balance between being robust enough for industrial applications while still being manageable for smaller lab environments.

For example, in industries like aerospace, automotive, and construction, materials must meet stringent safety and performance standards. The data generated by a 1000 pounds force tensile tester enables manufacturers to ensure their materials comply with these regulations, thereby reducing the risk of failure in real-world applications.

Applications Across Various Industries

1. Aerospace Engineering The aerospace sector relies heavily on tensile testing to evaluate materials used in aircraft components. A failure in this domain can lead to catastrophic consequences, so the rigorous testing of materials is non-negotiable.

1000 pounds force tensile tester exporter

2. Construction Building materials, including steel and concrete, are subjected to tensile tests to ensure their structural integrity. Understanding how these materials perform under stress helps architects and engineers design safer buildings.

3. Automotive Manufacturing In the automotive industry, tensile testing helps manufacturers choose materials that can withstand the demands of everyday use, including various climatic conditions and mechanical loads.

4. Textiles and Fabrics The textile industry also benefits from tensile testing to assess the strength and durability of fabrics, ensuring they can withstand wear and tear over time.

5. Medical Devices Tensile testers are employed in developing materials for medical devices, where reliability and strength are paramount to ensure patient safety.

The Export Market for Tensile Testers

As global industries continue to evolve and demand higher-quality materials, the export market for testing equipment, including 1000 pounds force tensile testers, is expanding rapidly. Countries with robust manufacturing and industrial sectors are the primary consumers of these machines. The growth of international trade and increased scrutiny on material safety standards have further propelled the demand for advanced testing equipment.

Exporters of tensile testers face the challenge of meeting diverse regulatory requirements across different countries. Compliance with international standards, such as ASTM and ISO, is crucial. Additionally, the technological advancement in tensile testing equipment, such as the integration of digital interfaces and automated data acquisition systems, makes these machines more attractive to international buyers.

Conclusion

The 1000 pounds force tensile tester plays an indispensable role in the material testing landscape, providing insights that help industries ensure safety, quality, and performance. As global demand for high-quality materials increases, the export market for these testing machines will likely continue to grow. By understanding the importance of tensile testing and investing in reliable testing equipment, industries can enhance their material selection processes, minimize risks, and ultimately improve the quality of their products. The ongoing innovation in this field promises a future where material testing becomes even more precise, efficient, and integral to manufacturing and engineering practices around the globe.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy