Exporters of 1000 Pound Force Tensile Testers for Quality Assurance Testing

The Market for 1000 Pound Force Tensile Testers An Overview

In today's dynamic manufacturing and materials testing industries, the demand for precise and reliable tensile testers is paramount. Among these, the 1000-pound force tensile tester stands out as an essential piece of equipment for a wide range of applications. From ensuring the integrity of materials to quality control in production processes, these testers play a vital role in various sectors, including textiles, plastics, metals, and aerospace.

Understanding Tensile Testing

Tensile testing is a fundamental process used to determine how materials will react under tensile (pulling) forces. The standard procedure involves elongating a sample material until it fails, allowing engineers to measure key properties such as tensile strength, yield strength, elongation, and reduction of area. This data is crucial for material selection and engineering design. A 1000-pound force tensile tester is capable of applying substantial force to a wide array of specimen types, making it an invaluable tool in laboratories and quality assurance settings.

Key Features of 1000 Pound Force Tensile Testers

When considering the export of 1000-pound force tensile testers, several key features make these machines attractive to international buyers

1. Precision and Reliability High-quality tensile testers are equipped with advanced electronic systems for accurate measurements. This precision is critical for compliance with international standards such as ASTM and ISO.

2. Versatility These testers can accommodate various materials, including metals, composites, plastics, and textiles, making them ideal for diverse industries.

3. User-Friendly Interfaces Modern tensile testers often feature user-friendly software, which provides automated data collection and analysis, enhancing productivity and reducing human error.

4. Portability and Compact Design For many laboratories, space is a premium. Many testers are designed to be compact yet robust, enabling users to conduct testing without the need for large dedicated spaces.

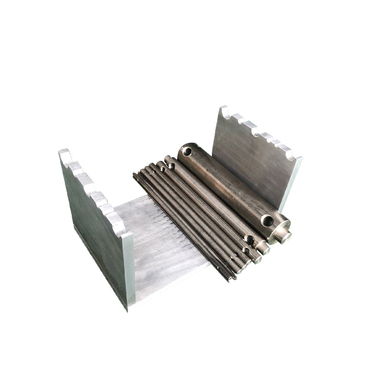

1000 pounds force tensile tester exporters

5. Robust Construction Exporters focus on building tensile testers that can withstand rigorous usage while minimizing maintenance needs, ensuring a long service life.

The Export Market

The market for 1000-pound force tensile testers is expanding, driven by technological advancements and a growing need for quality assurance in manufacturing processes. Exporters of these devices often aim at both established and emerging markets, where industrial growth fuels demand for advanced testing technology.

1. North America and Europe These regions are characterized by stringent quality standards in manufacturing. Thus, the demand for reliable tensile testing equipment is consistently high.

2. Asia-Pacific As countries like China and India experience rapid industrialization, there is a significant increase in demand for testing equipment. Exporters that can provide cost-effective yet high-quality solutions stand to gain substantial market share.

3. Latin America and the Middle East Emerging economies in these regions are witnessing increased investments in manufacturing and infrastructure, creating opportunities for exporters to introduce their technologies.

Challenges for Exporters

While the prospects appear promising, exporters of 1000-pound force tensile testers face several challenges, including differing regulatory standards across countries, intense competition, and fluctuating trade tariffs. Navigating these complexities requires exporters to invest in understanding local markets and compliance requirements to ensure successful entry and sustained growth.

Conclusion

In conclusion, the export of 1000-pound force tensile testers represents a significant opportunity within the global industrial landscape. By providing advanced, reliable, and versatile testing solutions, exporters can meet the growing demand for quality assurance in various sectors. With a strategic approach to market entry and a focus on innovation, the future of tensile tester exports looks bright, contributing to the development of robust manufacturing practices worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy