15 ton tensile tester

Understanding the 15% 20 Ton Tensile Tester

The 15% 20 ton tensile tester is a vital instrument in material science and engineering, designed to evaluate the tensile strength and ductility of various materials. This apparatus is essential for manufacturers, quality control labs, and research institutions seeking to understand how materials behave under stress.

What is a Tensile Tester?

A tensile tester, also known as a tensile testing machine or tensile strength testing machine, measures the force required to pull a material to the point of failure. The device extends the test specimen until it breaks, recording the applied force and the corresponding elongation. These data points allow engineers to determine the tensile strength, yield strength, elongation, and other crucial properties of the material.

Key Features of the 15% 20 Ton Tensile Tester

1. Load Capacity The '20 ton' designation indicates the maximum load the machine can handle, which is 20 tons or approximately 18.14 metric tonnes. This capacity is suitable for testing larger specimens and materials commonly used in construction, automotive, and aerospace industries.

2. Precision and Accuracy The '15%' refers to the specified margin of accuracy in measurements. This ensures that results are reliable and can be reproduced, making it a critical feature for labs that require strict adherence to testing standards. The enhanced precision helps in achieving consistent results vital for quality assurance processes.

3. Advanced Software Integration Modern tensile testers, including the 15% 20 ton model, often come with sophisticated software that enables users to monitor tests in real-time. This software can display stress-strain curves, calculate material properties automatically, and facilitate data analysis and reporting.

4. Versatile Test Configurations The tensile tester is equipped to handle various test configurations, including standard tensile tests, peel tests, and tear tests. This versatility allows material scientists to assess different aspects of material performance in a single machine.

15 ton tensile tester

Importance of Tensile Testing

Tensile testing plays a crucial role in materials engineering for several reasons

- Quality Control Manufacturers use tensile testers to ensure that their products meet specific standards and perform as expected under load. This is particularly important in sectors where material failure can lead to catastrophic results.

- Material Selection Engineers often face dilemmas when choosing materials for specific applications. Tensile testing provides critical data that assists in comparing different materials, ensuring the right choice for the intended application.

- Research and Development In R&D, understanding the mechanical properties of new materials is essential. The tensile tester aids researchers in developing innovative materials that meet evolving industry needs.

Conclusion

The 15% 20 ton tensile tester is an indispensable tool in the field of material science, playing a crucial role in ensuring the safety and reliability of products across various industries. With its high load capacity and precision, this machine empowers manufacturers and researchers alike to derive meaningful insights from their materials. As industries continue to prioritize safety and quality, the relevance of tensile testing will undoubtedly grow, solidifying the tensile tester's position as a cornerstone of material evaluation and development.

In summary, the 15% 20 ton tensile tester exemplifies the integration of technology and engineering, providing critical data that drives advancements in material performance and safety. Whether in a lab setting or an industrial environment, this device represents a commitment to quality and innovation in material testing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

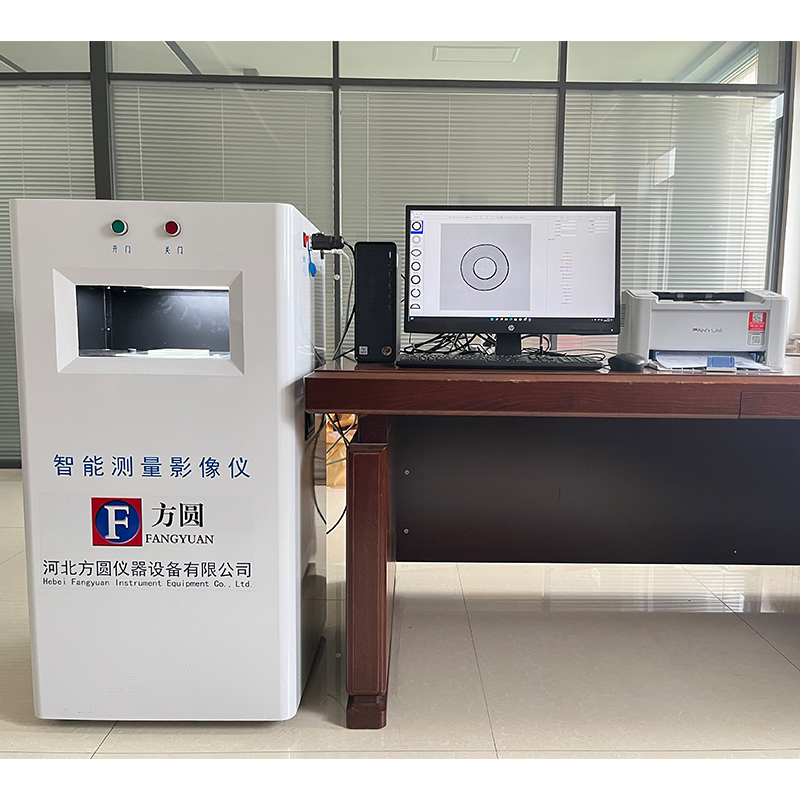

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy