High-Quality 20 Ton Tensile Testers from Leading Manufacturers and Suppliers

Exploring 15 Ton Tensile Tester Factories A Key Component in Material Testing

In today's manufacturing and engineering landscapes, the integrity and reliability of materials are paramount. This necessity has paved the way for specialized equipment, one of the most important being the tensile tester. A tensile tester is essential for assessing the strength and ductility of loads of materials, ensuring they can withstand the required operational conditions. Among the various models available, the 15 ton tensile tester has emerged as a preferred choice for many factories due to its efficiency and effectiveness in material analysis.

Understanding Tensile Testing

Tensile testing is a fundamental procedure applied across various industries, including construction, automotive, aerospace, and materials science. The process involves pulling a sample material until it fractures, measuring the force and elongation throughout the test. The results provide valuable data on tensile strength, yield strength, elongation, and reduction of area, which are critical parameters for assessing material performance.

The Role of 15 Ton Tensile Testers

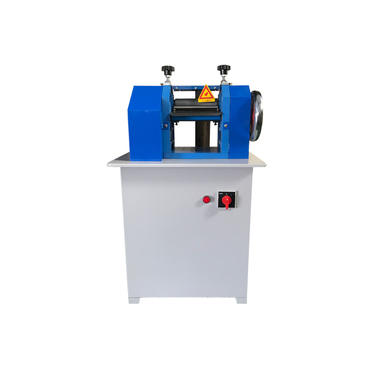

The designation 15 ton typically refers to the tester's capacity to apply up to 20 tons of force, which makes it an ideal tool for testing medium to high-strength materials. These testers are particularly beneficial when dealing with metals, plastics, composites, and other engineered materials.

Factories that utilize 15 ton tensile testers range widely, from those producing automotive components to manufacturers of construction materials. The versatility of this device allows for various applications, including tensile, compression, and bending tests. With the ability to simulate real-world conditions, manufacturers can ensure that their products are safe and reliable.

Key Features of 15 Ton Tensile Testers

1. Precision and Accuracy Modern tensile testers are equipped with advanced sensors and data acquisition systems that provide precise readings. This accuracy helps in meeting stringent industry standards and specifications.

2. User-Friendly Interface Many of these machines come with intuitive software that allows operators to easily set up tests, monitor performance in real-time, and analyze results efficiently.

15 ton tensile tester factories

3. Customization Certain factories may require specific customization of their tensile testers to suit unique material characteristics or testing conditions. Many manufacturers offer tailored solutions to accommodate these needs.

4. Durability Given the heavy-duty nature of tensile testing, these machines are built to withstand rigorous use. They feature robust construction, capable of maintaining accuracy over time, even under continuous testing scenarios.

5. Safety Features Safety is crucial in any testing environment. Many modern tensile testers include various safety features to protect both the equipment and the users. Emergency stop buttons, secure clamping mechanisms, and automatic shut-off systems are some examples.

Advantages for Factories

The use of 15 ton tensile testers offers several advantages for factories

- Quality Assurance By ensuring that materials meet specific strength criteria, manufacturers can deliver products that comply with industry regulations and customer expectations.

- Cost Efficiency Investing in a reliable tensile testing machine can reduce the costs associated with material failures, legal liabilities, and recalls. Identifying weaknesses in materials before they are used in products can save companies significant financial resources.

- Research and Development For companies involved in R&D, these testers provide the data necessary to innovate and improve material formulations, leading to better products and increased market competitiveness.

Conclusion

In conclusion, 15 ton tensile testers play a crucial role in the manufacturing and engineering sectors. Their ability to provide accurate, reliable, and essential data on material properties helps ensure the safety and quality of products across various industries. As factories continue to embrace advanced technologies and methodologies, the importance of tensile testing will only grow, paving the way for better materials and safer, more efficient production processes. Embracing these tools will empower companies to meet the challenges of today's market while maintaining a strong commitment to quality and innovation.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy