15 ton tensile tester manufacturer

The Significance of 15 Ton Tensile Tester Manufacturers in Material Testing

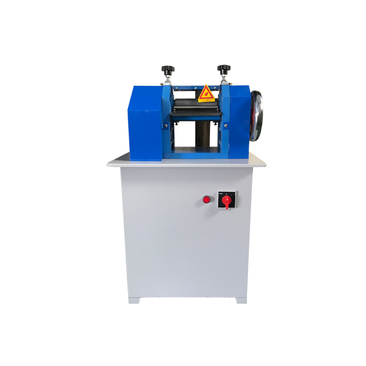

In the realm of materials science and engineering, the importance of tensile testing cannot be overstated. Tensile testers, particularly those with a capacity of 15 tons, play a crucial role in assessing the mechanical properties of materials, ensuring that they meet specified standards for various applications. The reliability of these testing devices is largely dependent on their manufacturers, who contribute significantly to the industry's integrity and innovation.

The Significance of 15 Ton Tensile Tester Manufacturers in Material Testing

The manufacturers of these tensile testers face unique challenges in ensuring their products meet industry standards and client requirements. These challenges include precision engineering, adherence to international testing standards such as ASTM and ISO, and the integration of advanced technology for enhanced accuracy. A reputable manufacturer will invest in quality control processes and research and development to produce robust and reliable testing equipment.

15 ton tensile tester manufacturer

Moreover, the rise of automation and smart technologies in manufacturing has influenced the design of tensile testers. Modern manufacturers are now incorporating digital interfaces, automated data collection, and analysis features, all aimed at improving the user experience and increasing efficiency. With features like real-time monitoring and data logging, engineers can analyze the material properties even during the testing process, saving time and reducing the likelihood of human error.

Selecting a manufacturer for a 15 ton tensile tester is a critical decision for businesses that rely on precise material testing. Key factors to consider include the manufacturer's reputation, the quality of customer service, the availability of technical support, and the warranty and service options. Engaging with a manufacturer that prioritizes innovation can also lead to access to the latest testing technologies and methodologies.

In addition, as industries shift towards sustainability, manufacturers of tensile testers are responding by developing environmentally friendly products. This is not only a trend but a necessity as businesses look to reduce their carbon footprint and operate in a more sustainable manner. The future of tensile testing therefore lies in the hands of manufacturers who can adapt to these changing demands while maintaining the accuracy and reliability of their equipment.

In conclusion, the role of 15 ton tensile tester manufacturers is vital in the field of materials testing. Their commitment to quality, innovation, and sustainability not only ensures compliance with industry standards but also supports the continuous improvement of material properties across various sectors. As technology evolves, these manufacturers will remain at the forefront, facilitating advances in materials science and engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy