Advanced Custom Optical Coordinate Measurement Solutions for Precision Engineering Applications

Custom Optical Coordinate Measuring Machine Enhancing Precision in Measurement

In the world of manufacturing and quality control, precision is paramount. The introduction of custom optical coordinate measuring machines (CMMs) has revolutionized the way we approach dimensional measurement. These sophisticated instruments provide manufacturers with the edge they need for accuracy, efficiency, and versatility in their operations.

Optical coordinate measuring machines utilize advanced optical techniques to gauge the dimensions of a variety of objects. Unlike traditional touch probes that measure physical contact points, optical CMMs employ non-contact methods, such as laser or video imaging, to capture the dimensions and geometries of parts. This not only enhances the speed of measurement but also significantly reduces the risk of damage to sensitive components, a critical advantage in industries producing fragile or finely machined products.

One of the standout features of custom optical CMMs is their configurability. Manufacturers often face unique challenges that require tailored solutions. Custom optical CMMs can be designed to accommodate specific types of parts, measurement tasks, and even unique environmental conditions. For instance, in environments where temperature fluctuations might affect measurement accuracy, these machines can be engineered with temperature control systems to maintain precision.

The adaptability of custom optical CMMs extends to the software that drives these machines. Advanced software solutions allow for complex data analysis, visualization, and reporting. Manufacturers can automate measurement processes, significantly reducing human error and time spent on inspections. The integration of software that utilizes artificial intelligence and machine learning algorithms can further enhance measurement accuracy and process efficiency. By predicting potential issues and offering real-time adjustments, these systems ensure that results are consistently reliable.

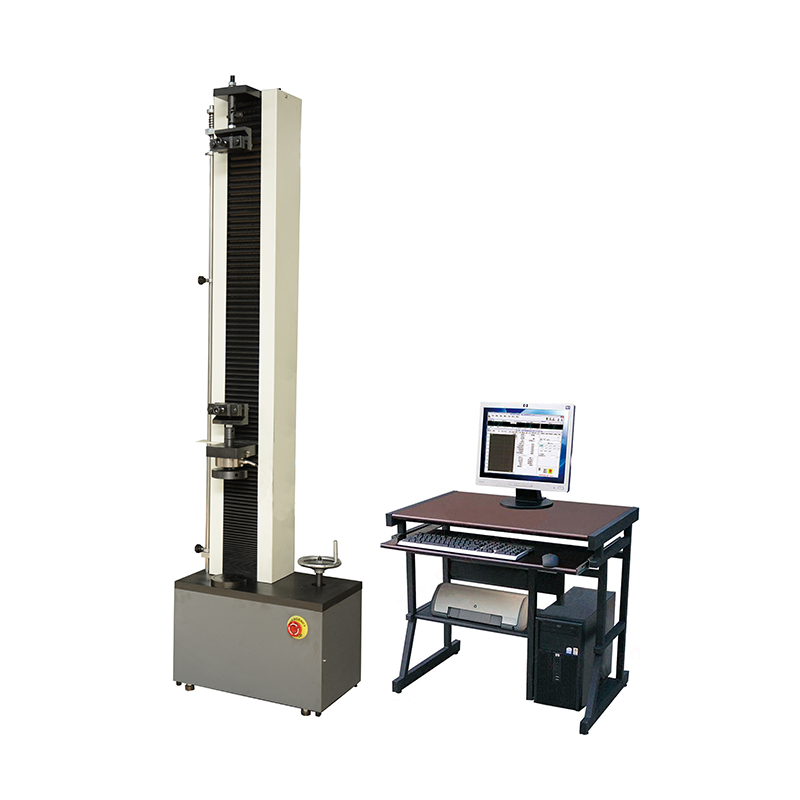

custom optical coordinate measuring machine

Moreover, custom optical CMMs stand out in industries such as aerospace, automotive, and medical device manufacturing, where regulatory compliance and stringent quality standards are non-negotiable. The machines can be integrated into existing workflows and quality management systems, ensuring that measurements are recorded meticulously for traceability and compliance purposes. With the ability to produce highly detailed 3D models, manufacturers can not only check dimensions but also analyze form and contour, driving improvements in design and production processes.

In addition to performance metrics, the financial aspect of implementing custom optical CMMs is often a critical consideration. While the initial investment may seem substantial, the long-term savings from reduced scrap rates, increased throughput, and enhanced product quality can be significant. Moreover, the ability to catch defects early in the manufacturing process can save companies substantial costs associated with rework and warranty claims.

Training and development also play a crucial role in the successful implementation of optical CMMs. Ensuring that staff are adequately trained to operate and maintain these sophisticated machines is essential. Manufacturers often invest in ongoing training programs to keep their workforce knowledgeable about the latest technological advancements and operational best practices.

In conclusion, custom optical coordinate measuring machines represent a significant advancement in precision measurement technology. Their non-contact measurement capabilities, customizable configurations, and integration with advanced software make them an invaluable asset in today's competitive manufacturing landscape. By enhancing accuracy, efficiency, and compliance, these machines not only meet the diverse needs of manufacturers but also contribute to the overall improvement of product quality and operational effectiveness. As industries continue to evolve, the role of optical CMMs in driving innovation and excellence is set to remain critical.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy