Top Suppliers for Aging Ovens in the Industry Today

The Evolution and Significance of Aging Ovens in the Industry

Aging ovens, also known as aging or seasoning ovens, are specialized heating devices utilized primarily in the manufacturing and treatment of various materials, especially metals and plastics. These ovens are integral in processes such as annealing, tempering, drying, and curing, contributing significantly to the improvement of material properties. As industries evolve, so does the technology and demand for aging ovens. This article examines the significance of aging ovens, their applications in various sectors, and the future landscape of their suppliers.

Understanding Aging Ovens

Aging ovens operate by maintaining controlled temperatures over extended periods, allowing for the gradual enhancement of material characteristics. The aging process can relieve internal stresses, optimize structural integrity, and enhance mechanical properties. These ovens are crucial in industries like aerospace, automotive, and electronics, where material reliability is paramount.

Although aging ovens have been in use for decades, advancements in technology have brought forth a range of modern aging ovens equipped with sophisticated control systems. These systems ensure uniform temperature distribution, reduce energy consumption, and enhance productivity, responding to the growing demands for efficiency and sustainability.

Applications Across Industries

1. Aerospace and Automotive In aerospace and automotive applications, aging ovens play an essential role in the heat treatment of various alloys, such as aluminum or titanium. These materials undergo aging to enhance strength and toughness, critical attributes for components that endure high levels of stress and extreme temperatures.

2. Electronics The electronics industry employs aging ovens for curing resins and coatings used in circuit boards and components. Proper aging ensures that these products meet their electrical and thermal specifications, contributing to longevity and performance.

3. Manufacturing In the manufacturing sector, aging ovens are used for treatment processes that improve the durability and performance of components. Whether it’s metal parts, plastics, or composites, the ability to control the aging process is vital for achieving desired properties.

The Role of Suppliers

The suppliers of aging ovens have a pivotal role in the advancement of these technologies. As industries demand more efficient and environmentally friendly solutions, suppliers must innovate to meet these needs. Challenges such as fluctuating raw material costs, regulations around emissions, and the necessity for energy-efficient machinery present both hurdles and opportunities for aging oven manufacturers.

aging ovens suppliers

Moreover, global competition has led suppliers to differentiate their products through advanced features such as automation, data acquisition, and integration with Industry 4.0 technologies. This embrace of smart manufacturing has empowered suppliers to provide ovens that not only perform better but also offer predictive maintenance and real-time monitoring capabilities.

Trends Shaping the Future of Aging Ovens

As we delve deeper into the 21st century, several trends are emerging that will shape the market for aging ovens

1. Sustainability There is a growing emphasis on environmentally friendly manufacturing processes. Aging oven suppliers are exploring options for reducing energy consumption and waste, including the use of alternative fuel sources and designs that optimize heat retention.

2. Technological Advancements The implementation of IoT (Internet of Things) technologies and automation in aging ovens is increasing. This enables manufacturers to monitor and control the aging process remotely, leading to more precise and efficient operations.

3. Market Expansion As developing countries enhance their manufacturing capabilities, the demand for aging ovens is expected to rise. Suppliers who can cater to these emerging markets by understanding local needs and providing scalable solutions are likely to gain a competitive edge.

4. Customization The increasing demand for bespoke solutions based on specific material requirements is compelling suppliers to offer custom-built aging ovens that meet unique customer specifications.

Conclusion

Aging ovens are more than just equipment; they represent an essential component of modern manufacturing that significantly impacts product quality and performance. The suppliers of these ovens stand at the crossroads of technology and industry needs, tasked with evolving their products to meet the challenges and demands of an ever-changing market. As advancements continue to reshape the landscape, the role of aging ovens in achieving higher quality outputs across various sectors will only grow, underscoring their importance in contemporary manufacturing practices.

In this dynamic environment, finding reliable suppliers who are committed to innovation and sustainability will be vital for businesses aiming to enhance their production processes and maintain a competitive edge.

-

Reliable CHJ Series Spark Tester for Insulation Quality Control

NewsSep.01,2025

-

QNJ-2/3 Cable Flexibility Test Machine: Precision & Durability

NewsAug.31,2025

-

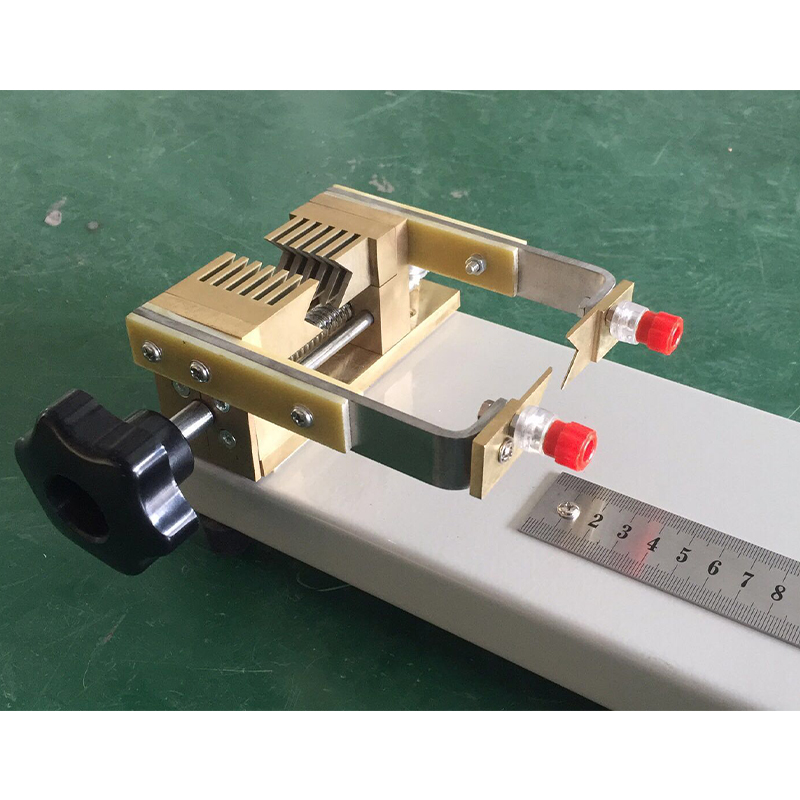

DQ-F Superfine Wire Conductor Resistance Fixture: High-Precision Testing

NewsAug.30,2025

-

ZC36 High Insulation Resistance: Reliable & Safe Performance

NewsAug.29,2025

-

CX-100 Manual Hydraulic Core Punching Machine - Efficient & Reliable

NewsAug.28,2025

-

Reliable Performance Testing with Advanced Aging Chamber Solutions

NewsAug.23,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy