aging test oven factories

The Importance of Aging Test Ovens in Manufacturing

In the realm of manufacturing, ensuring product durability and reliability is a top priority. One of the critical tools used in this process is the aging test oven. These specialized ovens are designed to simulate the long-term effects of environmental conditions on materials and products, allowing manufacturers to identify potential issues before they reach the market.

The Importance of Aging Test Ovens in Manufacturing

The significance of aging test ovens extends beyond just product testing. In industries such as electronics, automotive, and aerospace, the reliability of components is critical. A failure in these sectors can lead to serious consequences, including safety hazards and economic losses. Aging test ovens help mitigate these risks by providing data that informs design and manufacturing processes, ultimately enhancing product reliability and customer satisfaction.

aging test oven factories

Moreover, the use of aging test ovens also contributes to the sustainability of manufacturing processes. By identifying potential failures early, companies can reduce waste and avoid costly recalls. This proactive approach not only saves money but also minimizes environmental impact, as fewer defective products enter the waste stream. Thus, aging test ovens play a crucial role in fostering sustainable manufacturing practices.

Manufacturers are also increasingly utilizing advanced technologies in their aging test ovens, such as automated data collection and analysis. This integration of technology allows for more accurate and efficient testing processes. Real-time monitoring and analysis of test conditions enable factories to make informed adjustments, ensuring that products are subjected to the most relevant testing scenarios. As a result, companies can continuously improve their quality assurance practices.

In conclusion, aging test ovens are indispensable tools in manufacturing. They provide critical insights into product longevity and reliability, aiding companies in delivering high-quality goods to consumers. By utilizing aging test ovens, manufacturers can not only enhance their product offerings but also contribute to a more sustainable and efficient industry. As technology evolves, the importance of these ovens will only continue to grow, solidifying their place as a cornerstone of quality assurance in manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

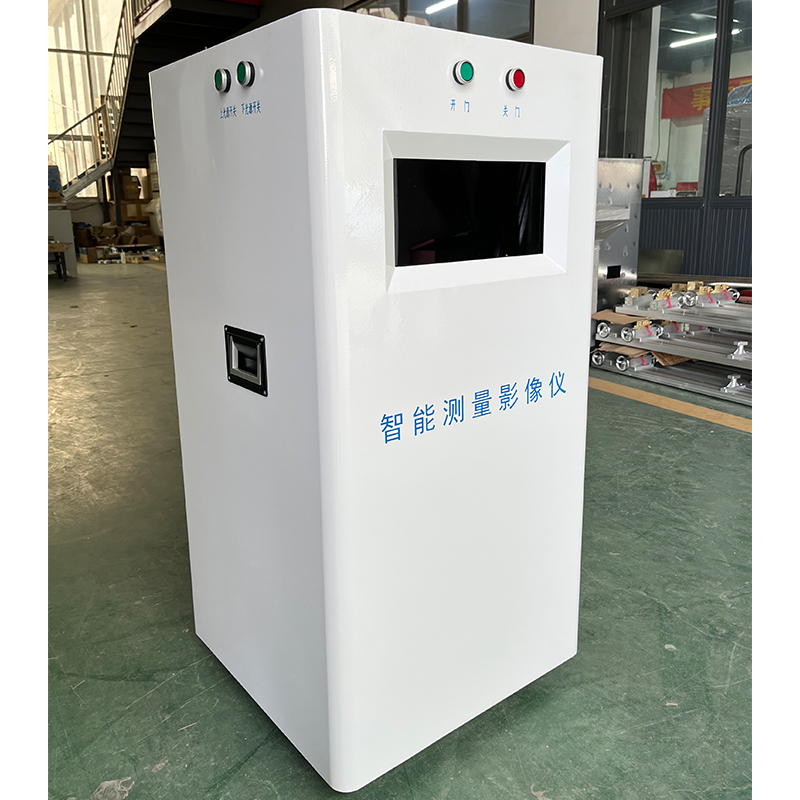

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy