Factory Solutions for Aging Test Ovens to Ensure Product Reliability and Performance

Aging Test Oven Factory Ensuring Reliability Through Rigorous Testing

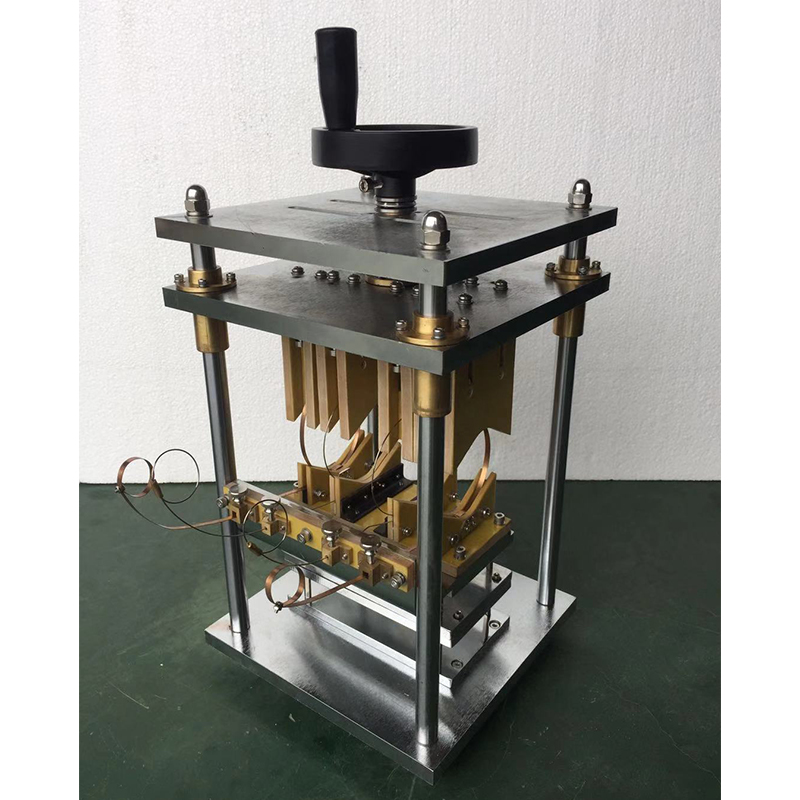

In the world of manufacturing, the integrity and reliability of products are paramount. As industries evolve, the demand for quality assurance has never been more critical. One of the essential tools used in this quest for reliability is the aging test oven. This article explores the significance, functionality, and production processes within an aging test oven factory.

Understanding Aging Test Ovens

Aging test ovens are specialized equipment used primarily to simulate prolonged exposure to high temperatures, humidity, and other environmental factors that materials or components might experience over time. These ovens are crucial in assessing the performance and durability of products before they reach the marketplace. By accelerating the aging process, manufacturers can identify potential failures, degradation, or changes in properties that might occur during the product's lifespan.

The Role of an Aging Test Oven Factory

An aging test oven factory plays a critical role in the manufacturing industry by producing these vital testing devices

. The factory is designed to meet strict quality control standards and is equipped with advanced technology to ensure that the ovens produced are not only reliable but also efficient. Each aging test oven is manufactured with precision to cater to various industries, including electronics, automotive, aerospace, and pharmaceuticals.Design and Manufacturing Process

The design and engineering teams within the factory begin by analyzing the specific requirements for different applications. The ovens need to accommodate various sizes and materials, ranging from small electronic components to larger mechanical parts. Once the specifications are established, the manufacturing process begins.

The first step in the production process is selecting the right materials. The structural components must withstand high temperatures and the internal environment must promote consistent heating and humidity levels. High-quality insulation materials are used to minimize heat loss, ensuring energy efficiency and consistent testing conditions.

aging test oven factory

Next, skilled technicians begin the assembly process. This involves precision engineering to ensure that every part fits perfectly, allowing accurate temperature readings and uniform heat distribution. Quality control measures are implemented at every stage to guarantee that the final product meets industry standards.

Once assembled, the ovens undergo rigorous testing. Each unit is subjected to various quality assurance protocols to assess its performance under simulated aging conditions. These tests verify that the ovens maintain consistent temperature and humidity levels and that they operate safely within intended parameters.

Innovation and Technology

The aging test oven factory continually embraces innovation and technology. Automation plays a significant role in enhancing the efficiency of production lines, allowing for faster turnaround times without compromising quality. Modern ovens are also equipped with digital interfaces, enabling precise control over time and environmental conditions, thereby facilitating easier monitoring and adjustments.

Moreover, the integration of data logging capabilities allows manufacturers to gather valuable insights during testing. This information is essential for fine-tuning products and processes, ultimately leading to improved durability and performance in the end products.

Customer Support and After-Sales Service

A reputable aging test oven factory also emphasizes customer support and after-sales service. Once a product is delivered, it is imperative to provide training and guidance to ensure that clients can operate the ovens effectively. Additionally, factories often offer maintenance services and support to address any operational issues that may arise.

In conclusion, aging test ovens are an indispensable aspect of quality assurance in manufacturing. The collaborative efforts of design, engineering, and production within aging test oven factories ensure that these vital testing devices meet the rigorous demands of various industries. As technology advances and industries evolve, the role of aging test ovens will only grow more critical, reinforcing the commitment to producing reliable and durable products for consumers worldwide. The future of manufacturing is bright, with aging test ovens leading the way in quality assurance and product integrity.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy