A Conventional Tensile Testing Equipment Manufacturer for Quality Material Analysis

Exploring the World of Traditional Tensile Tester Companies

In the realm of materials testing, few instruments are as essential as the tensile tester. From the aerospace industry to manufacturing, these machines are pivotal in evaluating the strength and ductility of various materials. Among the many manufacturers in this field, traditional tensile tester companies stand as stalwarts, offering reliable, time-tested equipment to meet the rigorous demands of material testing.

A traditional tensile tester, also known as a universal testing machine (UTM), is designed to apply controlled tension to a sample until it fails. This process not only determines ultimate tensile strength (UTS) but also provides insights into other critical properties such as yield strength, elongation, and reduction of area. The fundamental principle remains unchanged; however, advancements in technology have improved the precision and efficiency of these testers significantly.

Companies that have built their reputations on traditional tensile testing equipment often focus on three key areas precision, durability, and user-friendliness. Precision is paramount in materials testing, as any discrepancy can lead to faulty product designs or safety issues. Traditional tensile tester companies invest in high-quality components and engineering to ensure their machines deliver accurate results. These machines often utilize hydraulic or electromechanical systems, providing users with a range of load capacities and testing speeds suitable for various materials, from metals to polymers.

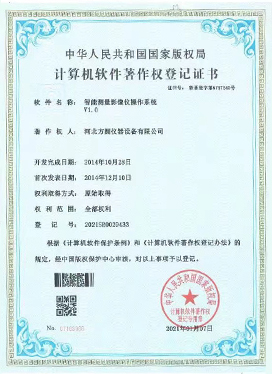

a traditional tensile tester company

Durability is another hallmark of traditional tensile testers. The machines are engineered to withstand the wear and tear of continuous use in often demanding industrial environments. High-quality materials and robust construction techniques ensure that these testers operate consistently over long periods, minimizing downtime and maintenance costs for users.

User-friendliness is increasingly important in the modern landscape of materials testing. Traditional tensile tester companies are adapting to this demand by incorporating intuitive interfaces and software that facilitate ease of use. Modern systems often come equipped with advanced data acquisition and analysis capabilities, allowing engineers to assess material properties swiftly and accurately. This integration of user-friendly features makes it easier for both seasoned professionals and newcomers to navigate the complexities of material testing.

Moreover, the heritage and craftsmanship associated with traditional tensile tester companies enhance their appeal. Many businesses in this sector have decades, if not centuries, of experience. This legacy builds trust among users, who often prefer equipment from manufacturers with a proven track record of reliability and performance.

In conclusion, while the landscape of materials testing continues to evolve with technology, traditional tensile tester companies remain invaluable. Their commitment to precision, durability, and user-friendly design ensures that they will continue to play a crucial role in industries reliant on high-quality materials. As new challenges arise in materials science, these companies will undoubtedly adapt and innovate, maintaining their status as leaders in the field of tensile testing. For industries looking to uphold quality standards, traditional tensile testers are an investment in reliability and excellence.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy