Exploring the Features of Conventional Tensile Testing Equipment in Manufacturing Facilities

The Role of Traditional Tensile Tester Factories in Material Testing

In the realm of material science, testing the tensile strength of materials is paramount. This is where traditional tensile tester factories play a crucial role. These factories specialize in the production of tensile testing machines that ensure materials meet industry standards for strength, durability, and safety.

Tensile testing involves the application of a controlled force to a material specimen until it deforms or ultimately breaks. This process provides essential data on the material’s mechanical properties, including yield strength, ultimate tensile strength, elongation, and reduction of area. Traditional tensile tester factories have honed their expertise over decades, providing reliable machinery that serves various industries, from construction to aerospace.

One of the key advantages of traditional tensile tester factories is their deep-rooted knowledge of material behavior under stress. These factories invest significant time and resources in research and development to improve their products continually. Their machines are designed to withstand rigorous testing conditions while delivering accurate and repeatable results. Operators can perform tests on metals, plastics, textiles, and composites, ensuring versatility in testing capabilities.

a traditional tensile tester factories

Quality control is another critical facet of these factories. Each tensile testing machine is manufactured to exacting standards, often complying with international testing norms such as ASTM or ISO. This guarantees that the equipment will perform reliably in various settings. Traditional factories typically maintain a strong connection with their customers, allowing for customization based on specific testing needs, which is essential for industries that require unique specifications.

Moreover, traditional tensile tester factories contribute significantly to the local economy. They provide skilled jobs and support the workforce development of technicians and engineers proficient in material testing and quality assurance. Through their commitment to excellence, they enhance the overall technological capabilities of their regions, fostering innovation and competitiveness.

However, as industries evolve and the demand for precise testing increases, some traditional factories are adapting to modern challenges. Incorporating digital technology and automation into their machinery enhances the efficiency and accuracy of tensile testing. This evolution does not imply a decline in craftsmanship; rather, it is a fusion of traditional engineering expertise with modern technological advancements.

In conclusion, traditional tensile tester factories are integral to the material testing landscape. Their commitment to quality, precision, and innovation ensures that manufacturers can rely on the materials they use in their products. As industries continue to grow and diversify, these factories remain at the forefront, providing the tools necessary for ensuring material integrity and performance across a myriad of applications. The synergy between traditional methods and modern technology will undoubtedly shape the future of material testing, leading to safer and more reliable products in the marketplace.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

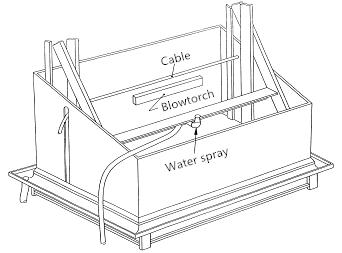

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy