Suppliers of Classic Tensile Testing Equipment for Material Strength Evaluation

Understanding the Importance of Traditional Tensile Tester Suppliers

In the world of materials testing, the significance of a reliable tensile tester cannot be overstated. These devices are crucial for determining the tensile strength and ductility of various materials, from metals and plastics to construction materials and textiles. In this context, traditional tensile tester suppliers play a vital role in ensuring that industries have access to quality testing equipment, thus maintaining safety and quality standards across various sectors.

What is a Tensile Tester?

A tensile tester, also known as a tensile testing machine or a materials testing machine, is designed to measure how materials react to forces that are applied in tension. The fundamental goal is to determine a substance's strength and elongation properties before it fails under stress. The tester applies a pulling force to a sample, measuring the amount of deformation that occurs up to the breaking point. This process aids engineers and manufacturers in understanding material behavior, which is essential for product design and quality control.

The Demand for Quality Testing Equipment

As industries evolve and technological advancements continue, the demand for more robust and reliable materials testing machines has escalated. Traditional tensile tester suppliers have been responding to these needs through consistent innovation and enhancement of their offerings. They not only provide testing machines that conform to international standards, but also adapt to the specific requirements of different industries.

Suppliers of traditional tensile testers establish their business on decades, if not centuries, of expertise in materials science and engineering. Their machines are designed to be user-friendly while delivering accurate results that can be replicated, ensuring reliability in testing procedures. This commitment to quality not only helps businesses produce safer products but also complies with global regulatory standards.

The Role of Traditional Vendors in Market Evolution

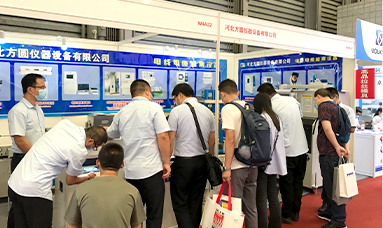

a traditional tensile tester suppliers

Traditional tensile tester suppliers have had to adapt to a rapidly changing market landscape. In an age where digitalization and automation are becoming the norm, many suppliers have incorporated advanced technology into their machines. Modern tensile testers now often feature digital displays, computer interfaces, and even software for data analysis. However, traditional suppliers maintain a balance by honoring the reliability and simplicity that made their machines popular in the first place.

Another advantage of working with established suppliers is their deep understanding of industry needs across various sectors. They offer tailored solutions that meet specific testing requirements for different materials, ensuring that manufacturers obtain the relevant mechanical properties they need. This level of customization sets traditional suppliers apart from newer, more generic providers in the market.

Quality Assurance and Customer Service

The relationship between manufacturers and traditional tensile tester suppliers is built on trust and quality assurance. Established suppliers often provide not only equipment but also comprehensive training and support services. Users of tensile testing machines may require guidance on how to interpret data accurately or troubleshoot any issues that arise during testing. A reliable supplier not only sells a machine but also ensures that the customer fully understands how to utilize it effectively.

Additionally, traditional suppliers invest in regular calibration and maintenance services to ensure that machines remain in peak operational condition. They understand that the accuracy of material testing directly impacts product safety and quality. These services are paramount for manufacturers who cannot afford downtime or errors in testing results.

Conclusion

In conclusion, traditional tensile tester suppliers hold a critical place within the materials testing ecosystem. They provide essential equipment that allows industries to test, evaluate, and refine their products, thereby enhancing quality and safety standards. With a commitment to quality manufacturing, customer service, and an ability to adapt to evolving technology, these suppliers continue to thrive in a competitive market. As industries look to the future, relying on established suppliers for tensile testing equipment will remain invaluable, ensuring that both safety and innovation can go hand in hand.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy