automatic measuring projector company

Understanding the Role of Automatic Measuring Projector Companies in Precision Engineering

In the realm of precision engineering, the importance of accurate measurement cannot be overstated. This is where automatic measuring projector companies come into play, offering advanced solutions that cater to the needs of industries requiring exact specifications. These high-tech devices are essential for quality control and assurance processes across various sectors, such as manufacturing, automotive, aerospace, and electronics.

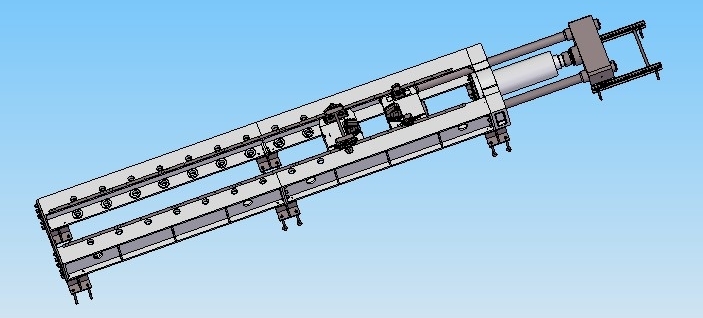

An automatic measuring projector, also known as a profile projector or optical comparator, utilizes optical magnification and precise measurement capabilities to project the silhouette of a part onto a screen. This allows engineers and quality control personnel to evaluate the dimensions of the part against its intended specifications. The automation aspect of these projects helps in enhancing productivity, reducing human error, and ensuring consistency in measurements.

Companies specializing in this technology invest heavily in research and development to stay ahead in an increasingly competitive market. They continuously innovate their design and technology to integrate features such as digital displays, automatic measurement functions, and software capabilities that can interpret data with high precision. Additionally, many of these companies focus on user-friendly interfaces that allow personnel to operate the machines with minimal training.

automatic measuring projector company

One of the significant advantages of automatic measuring projectors is their versatility. They can measure a wide range of geometrical features, including radius, angles, and linear dimensions. This versatility makes them invaluable in various applications, from simple component checks to intricate diagnostic processes in complex assemblies.

Moreover, with the advent of Industry 4.0, many automatic measuring projector companies are embracing connectivity and smart technology. These devices can now send measurement data straight to a centralized database or a computer system for analysis. This real-time data acquisition plays a crucial role in predictive maintenance, reducing downtime, and improving product quality.

As manufacturers strive for lean production and cost-efficiency, automatic measuring projectors are becoming increasingly vital. They not only enhance the accuracy of production but also reduce waste by identifying defects at an early stage. In an era where quality and precision are paramount, the contributions of automatic measuring projector companies cannot be overlooked.

In conclusion, automatic measuring projector companies play a critical role in the precision engineering landscape. By providing sophisticated measurement solutions, they help industries maintain high standards of quality and efficiency. As technology continues to evolve, we can anticipate further advancements in this field, making these devices even more integral to modern manufacturing processes.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy