Automatic Optical Measurement Machines | Precision Measurement Solutions

The Emergence of Automatic Optical Measurement Machines Pioneering Precision in Manufacturing

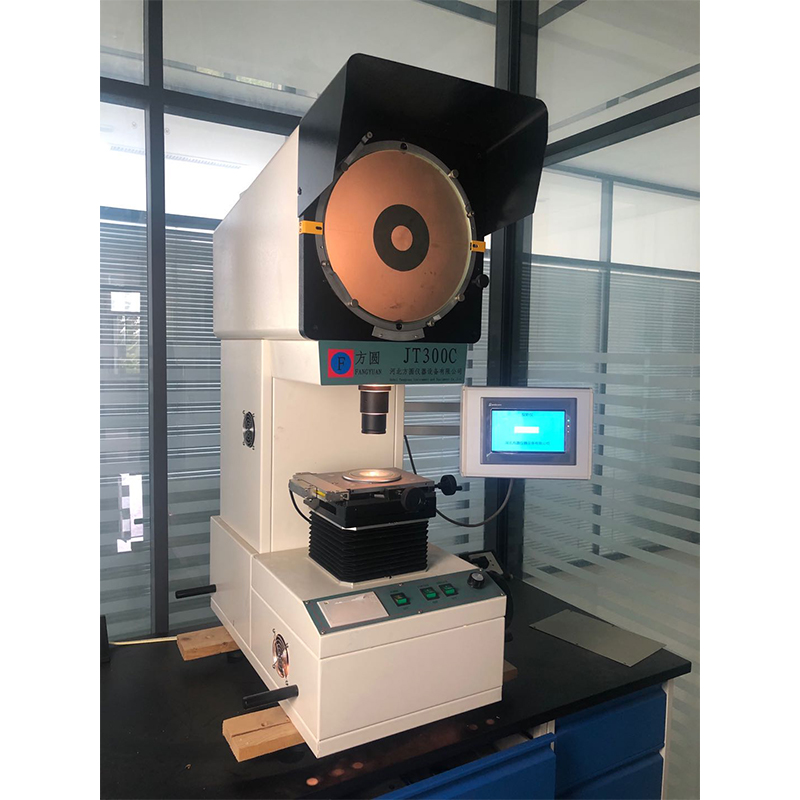

In recent years, the manufacturing industry has witnessed a technological revolution driven by automation and advanced measurement systems. Among these innovations, Automatic Optical Measurement Machines (AOMMs) have emerged as crucial tools that enhance precision, speed, and efficiency in the quality control processes of various sectors.

Automatic Optical Measurement Machines utilize sophisticated optical technologies to measure the geometrical characteristics of objects. These machines seamlessly integrate advanced imaging systems, computer algorithms, and often laser technologies to provide highly accurate measurements without the need for physical contact with the workpiece. This non-contact measurement technique is particularly advantageous for delicate components that may be easily damaged.

The importance of AOMMs stems from their ability to ensure quality control in the production line. With increasing demands for higher precision and reduced production costs, manufacturers are turning to automated systems to maintain competitive advantages. AOMMs offer rapid measurement capabilities, significantly shortening production cycles while enhancing the consistency of product quality. This feature is especially important in industries such as electronics, automotive, and aerospace, where the tolerances are incredibly tight, and any deviation can lead to substantial issues down the line.

One of the standout features of Automatic Optical Measurement Machines is their versatility. They can be employed for various applications, including the measurement of flatness, thickness, and dimensional accuracy of intricate components. Moreover, AOMMs can handle a wide range of materials—from plastics and metals to ceramics—making them indispensable in modern manufacturing plants.

automatic optical measurement machine company

The data generated by AOMMs can be integrated into production management systems, providing manufacturers with real-time insights into their processes. This capability facilitates a more proactive approach to quality control, enabling manufacturers to identify potential issues before they escalate into costly problems. The information can also be utilized for continuous improvement initiatives, allowing for the optimization of production workflows.

The adoption of AOMMs is not without challenges. Implementing such advanced technology requires an initial investment in equipment and training for personnel. Manufacturers must also adapt their processes to leverage the benefits of automation fully. However, as the benefits of increased precision, reduced waste, and enhanced productivity become apparent, many companies view the investment as a necessary step toward modernization.

As we look to the future, the role of Automatic Optical Measurement Machines is set to expand. With advancements in artificial intelligence and machine learning, we can expect even greater efficiencies and capabilities in measurement systems. These technologies promise to augment the capabilities of AOMMs, making them more autonomous and capable of providing deeper insights into production quality.

In conclusion, Automatic Optical Measurement Machines represent a significant advancement in the quest for precision in manufacturing. Their ability to provide fast, accurate, and non-destructive measurements makes them invaluable in today’s high-stakes production environments. As industries continue to seek innovative solutions to improve their processes and ensure quality, AOMMs will undoubtedly play a pivotal role in shaping the future of manufacturing. Embracing this technology is not merely an option but a necessity for staying competitive in a rapidly evolving marketplace.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy