automatic measuring projector companies

The Rise of Automatic Measuring Projector Companies in Precision Measurement Technology

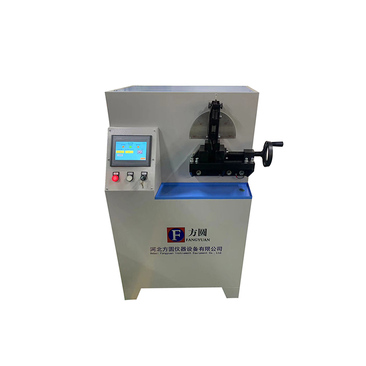

In an era where accuracy and efficiency are paramount in manufacturing and quality control, the automatic measuring projector has emerged as a vital tool for industries ranging from automotive to aerospace. These devices, designed to provide precise dimensional measurements of various components, have gained traction among manufacturers who prioritize precision engineering and stringent quality standards. As a result, companies specializing in the production and development of automatic measuring projectors are becoming increasingly significant players in the precision measurement technology sector.

What is an Automatic Measuring Projector?

An automatic measuring projector, commonly known as a shadow or optical projector, utilizes light and magnification techniques to project the silhouette of an object onto a screen. This projection enables operators to take critical measurements quickly and accurately. The equipment is equipped with advanced optics and digital measuring capabilities, allowing for automatic calibration and data logging, which significantly reduces the chances of human error during inspections. This technology is especially beneficial in high-volume production settings where consistency and repeatability are required.

Key Players in the Industry

Several companies dominate the market for automatic measuring projectors, each bringing unique innovations and quality controls to the table. Leaders like Mitutoyo, Nikon, and Zeiss have established themselves through decades of expertise and product development. These firms not only manufacture measuring projectors but also invest heavily in research to enhance measurement capabilities and incorporate digital technologies.

Mitutoyo, for instance, is renowned for its commitment to precision and quality. Their range of automatic measuring projectors is equipped with advanced software that allows for complex measurement tasks, regionalized settings, and enhanced data output capabilities. This positions them as a frontrunner in industries that demand high precision, such as the semiconductor and optical component sectors.

automatic measuring projector companies

Nikon, similarly, focuses on integrating cutting-edge technology into its measuring instruments. Their automatic measuring projectors utilize digital image processing to ensure high-definition measurements, making them ideal for intricate component inspection. Furthermore, Nikon's continuous investment in research and development keeps them at the forefront of innovation in measurement technology.

The Future of Measuring Projectors

The future of automatic measuring projector companies seems promising as industries continue to evolve towards higher standards of precision and automation. The integration of artificial intelligence and machine learning into measurement systems is poised to revolutionize how companies approach quality assurance. Predictive maintenance, real-time data analysis, and enhanced user interfaces are just a few developments that could emerge from these technological advancements.

Moreover, with the rise of Industry 4.0, manufacturers are increasingly looking for ways to streamline operations through automation. Automatic measuring projectors will play a crucial role in this transformation by providing real-time feedback and measurements that can be integrated into manufacturing processes. This ensures that companies can maintain quality standards while increasing production efficiency.

Conclusion

In conclusion, the growth of automatic measuring projector companies signifies a shift towards more precise and automated manufacturing processes in various industries. As technology continues to advance, these companies are likely to lead the charge in developing solutions that cater to the evolving needs of precision measurement. Their role is increasingly vital in ensuring that industries can meet the demands of both efficiency and accuracy, which are essential in today’s competitive landscape. Investing in such technology is not just about keeping up; it's about setting the benchmarks for quality and precision in manufacturing worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy