automatic optical measurement machine exporter

Exploring the Role of Automatic Optical Measurement Machines in Exporting Industries

Automatic Optical Measurement Machines (AOMMs) have become integral tools in various manufacturing and quality control processes across different industries. These sophisticated instruments are designed to facilitate precise measurements of components and materials, ensuring they meet the specified tolerances and quality standards. The significance of AOMMs is particularly pronounced in the context of exporters, where maintaining high quality and compliance with international standards is paramount.

Understanding Automatic Optical Measurement Machines

AOMMs utilize advanced optical technology to enable the measurement of a wide range of parameters, including dimensions, surface defects, and geometric tolerances. By employing high-resolution cameras and sophisticated image processing algorithms, these machines can deliver measurements with exceptional accuracy. The use of AOMMs is prevalent in sectors such as electronics, automotive, aerospace, and medical devices, where even minor deviations can lead to significant operational issues or safety hazards.

Benefits for Exporters

1. Quality Assurance For exporters, the primary benefit of using AOMMs lies in the enhancement of quality assurance processes. These machines offer a non-contact measurement technique, which reduces the risk of damaging delicate components during the inspection process. By ensuring that products meet stringent international quality standards, exporters can build trust with global clients and enhance their reputation in international markets.

2. Increased Efficiency The automation of measurement processes leads to substantial time savings. Traditional measurement methods often involve manual checks, which can be time-consuming and prone to human error. AOMMs streamline the inspection process, allowing for rapid assessments without compromising accuracy. This increased efficiency is crucial for exporters who operate under tight deadlines, enabling them to meet customer demands promptly.

automatic optical measurement machine exporter

3. Consistency in Production Consistency is essential for maintaining competitive advantage in the export market. AOMMs provide uniform measurement results, which help in identifying and rectifying variations in the manufacturing process. This capability ensures that each batch of products adheres to the same quality standards, minimizing the risk of defects that could hinder export processes.

4. Cost-Effectiveness While the initial investment in AOMMs may seem significant, the long-term cost benefits are undeniable. By reducing the likelihood of recalls, reworks, and scrapped materials, these machines can significantly lower operational costs. Furthermore, the ability to produce high-quality products consistently can lead to greater customer satisfaction and repeat business, ultimately boosting revenue for exporters.

Compliance with International Standards

International markets often require compliance with specific quality standards and regulations. Utilizing AOMMs assists exporters in adhering to these mandatory requirements, reducing the risk of penalties and product recalls. Accreditation bodies often favor companies that implement advanced measurement technologies, which can also facilitate smoother entry into foreign markets.

Conclusion

In conclusion, Automatic Optical Measurement Machines play a crucial role in the landscape of exporting industries. Their ability to provide accurate, efficient, and consistent measurements not only enhances product quality but also streamlines manufacturing processes. As globalization continues to shape the market dynamics, exporters must leverage innovative technologies like AOMMs to maintain competitiveness and ensure successful market penetration. Investing in these advanced measurement tools is not just a strategic move for quality assurance but a vital step towards achieving long-term growth and sustainability in the global export arena.

-

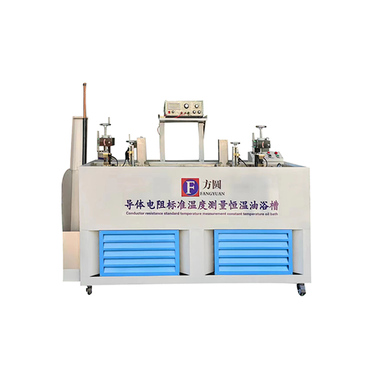

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy