automatic optical measurement machine supplier

The Role of Automatic Optical Measurement Machines in Modern Manufacturing

In today's fast-paced manufacturing landscape, precision and accuracy are paramount. As industries strive for greater efficiency and quality control, the need for advanced measurement tools has become increasingly critical. One of the most transformative innovations in this sphere is the automatic optical measurement machine (AOMM). This technology not only enhances productivity but also revolutionizes the way manufacturers approach quality assurance.

Automatic optical measurement machines play a pivotal role in ensuring that components meet exact specifications. Unlike traditional measurement techniques, which often rely on manual intervention, AOMMs utilize sophisticated optical sensors and advanced imaging technologies to perform precise measurements automatically. This capability not only speeds up the inspection process but also minimizes human error, resulting in higher accuracy and consistency in measurements.

Key Features of Automatic Optical Measurement Machines

AOMMs are equipped with various features that make them indispensable in manufacturing environments. One of the standout features is their non-contact measurement capability, allowing them to measure delicate or sensitive components without causing any damage. This is particularly useful in industries such as electronics, automotive, and aerospace, where even the slightest deviation in component dimensions can lead to significant failures.

Additionally, these machines often incorporate advanced software for data analysis and reporting. This allows manufacturers to quickly identify deviations from specifications and implement corrective actions. The integration of software tools enhances the overall functionality of AOMMs, enabling them to not only measure dimensions but also perform complex analyses such as comparing actual data against CAD models.

Efficiency and Productivity Gains

automatic optical measurement machine supplier

The automation of measurement processes through AOMMs leads to significant improvements in efficiency and productivity. Since these machines can operate continuously without fatigue, they enable manufacturers to maintain a higher throughput. Continuous operation is particularly beneficial for industries with high production volumes, as it alleviates bottlenecks commonly encountered during manual inspection processes.

Moreover, the rapid measurement capabilities of AOMMs mean that manufacturers can obtain real-time feedback on production quality. This agility allows for quicker adjustments and optimizations in production processes, leading to reduced waste and lower operational costs. Enhanced productivity ultimately translates into increased competitiveness in the global market, making AOMMs an attractive investment for manufacturers.

Versatility Across Industries

The versatility of automatic optical measurement machines is remarkable, as they can be adapted to a wide range of applications across various industries. From inspecting microelectronic components to measuring large automotive parts, AOMMs can be tailored to meet the specific measurement needs of different sectors. Their adaptability ensures that as manufacturing processes evolve, these machines remain relevant and effective.

In addition to their use in manufacturing, AOMMs are also valuable in research and development environments. Engineers and designers can utilize these machines to prototype and test new components rapidly, facilitating innovation and speeding up time-to-market for new products.

Conclusion

In conclusion, the advent of automatic optical measurement machines is transforming the landscape of modern manufacturing. Their ability to provide fast, accurate, and non-contact measurements makes them essential for quality control processes. With benefits such as increased efficiency, reduced costs, and versatile applications across multiple industries, AOMMs are becoming a cornerstone of effective manufacturing practices. As technology continues to advance, we can expect further innovations in measurement solutions, further solidifying the role of AOMMs in enhancing manufacturing excellence. The future of manufacturing is undoubtedly bright, and automatic optical measurement machines are at the forefront of this evolution.

-

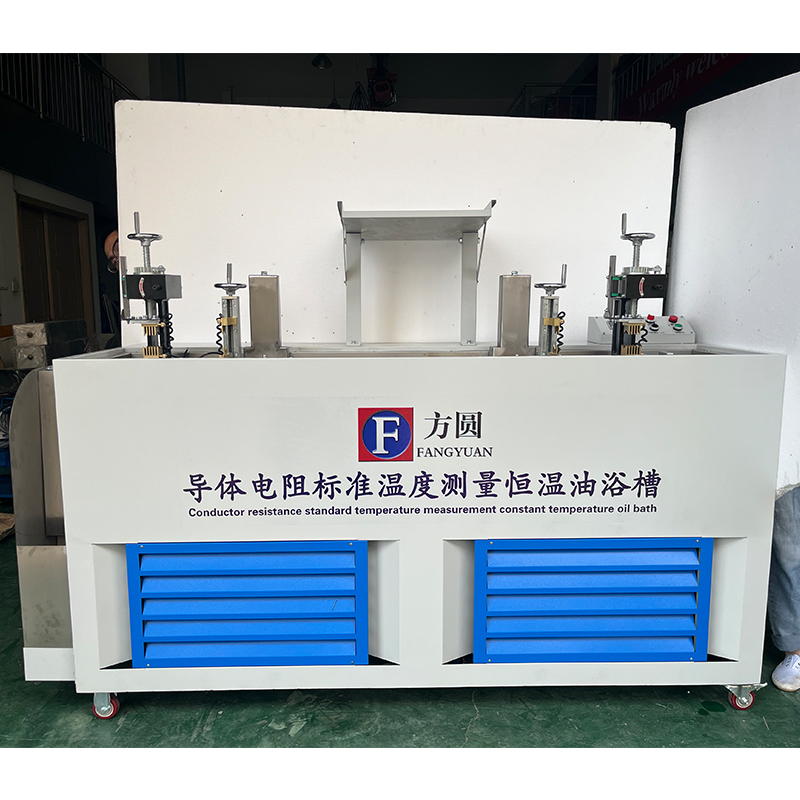

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy