bench resistance tester manufacturers

Understanding the Role of Bench Resistance Tester Manufacturers

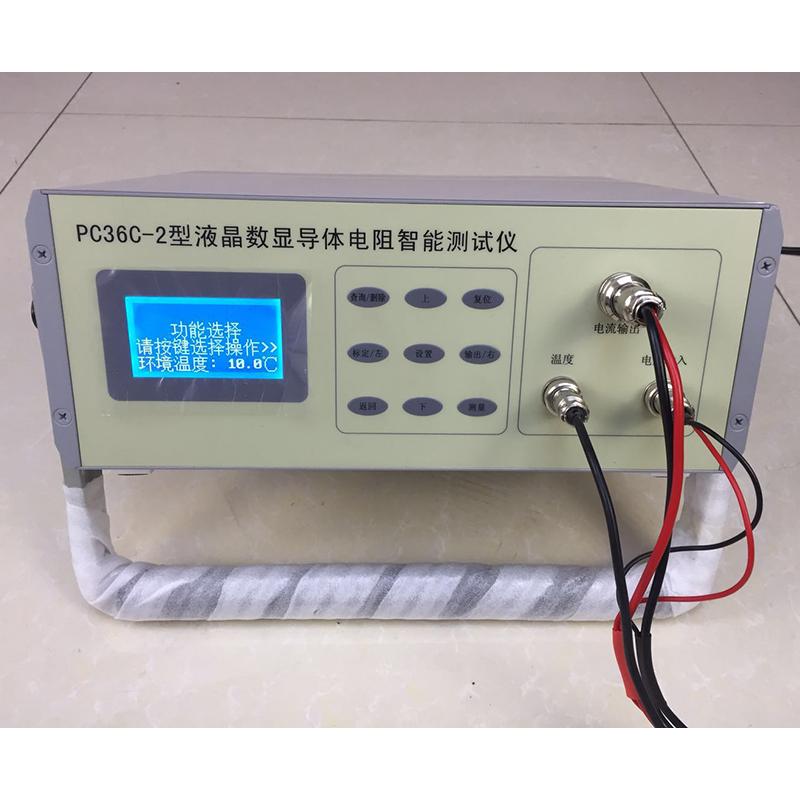

In the ever-evolving landscape of electrical engineering, precision and reliability are paramount, particularly when it comes to the testing and measurement of resistance in various components. Bench resistance testers are essential tools that facilitate these measurements, ensuring that devices operate within their specified parameters. As such, the role of bench resistance tester manufacturers becomes highly significant, as they not only produce these instruments but also influence the standards and quality of testing equipment available in the market.

What is a Bench Resistance Tester?

A bench resistance tester is a specialized device designed to measure the electrical resistance of components, circuits, and materials. It functions by applying a known voltage to the sample and measuring the resulting current, complying with Ohm's law (V = I × R). These testers are widely used in laboratories, manufacturing plants, and test facilities for quality control, research, and development purposes.

Importance of Quality and Reliability

The quality of bench resistance testers directly impacts the accuracy of the measurements taken. Manufacturers must adhere to strict quality control measures to produce reliable instruments capable of providing precise readings under various conditions. This importance is amplified in industries such as automotive, aerospace, and telecommunications, where even the slightest deviation in resistance measurement can lead to catastrophic failures. A reputable manufacturer invests in research and development to innovate and enhance the performance of their testers, ensuring they meet the necessary industry standards.

Features of Modern Bench Resistance Testers

bench resistance tester manufacturers

Modern bench resistance testers come equipped with a broad range of features designed to enhance usability and functionality. Many models include digital readouts, automatic range selection, and data logging capabilities. Some advanced testers can communicate with computers and other devices, allowing for seamless data transfer and analysis. In addition to basic resistance measurements, some testers can perform additional tasks such as insulation resistance testing and high-pot testing, providing versatility to users.

The Manufacturing Process

The manufacturing process of bench resistance testers involves several critical steps, including design, sourcing of materials, assembly, testing, and quality assurance. Manufacturers often collaborate with engineers and industry experts during the design phase to ensure the features and specifications align with market needs. Sourcing high-quality components is crucial, as the performance of the final product heavily depends on the internal parts used, including resistors, capacitors, and microcontrollers.

After assembly, each device undergoes a rigorous testing phase where it is calibrated and validated against industry standards. This ensures that the testers will perform accurately and reliably in real-world applications. Quality assurance processes help identify and rectify any potential defects before the product reaches consumers, safeguarding the manufacturer’s reputation and the customer’s investment.

Future Trends and Innovations

As technology progresses, bench resistance tester manufacturers are adapting to incorporate new advancements in electronics and software. The trend towards automation and smart devices is paving the way for more sophisticated testing instruments. Integration with IoT (Internet of Things) technologies could enable remote monitoring and diagnostics, making it easier for engineers to assess resistance levels in real time regardless of their location.

In conclusion, bench resistance tester manufacturers play a vital role in ensuring high-quality electrical testing equipment is available across various industries. Their commitment to innovation, quality control, and customer satisfaction not only enhances the reliability of electronic devices but also promotes advancements in technology, making them indispensable in today’s fast-paced, tech-driven world. As these manufacturers continue to evolve, they will undoubtedly help shape the future of electrical testing and measurement.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy