brands tensile tester factories

Understanding Brands and Their Impact in the Tensile Tester Manufacturing Industry

In the realm of material science and testing, tensile testing is a fundamental method used to determine the mechanical properties of materials. This process plays a crucial role in ensuring the quality and reliability of materials used in various industries, including construction, automotive, aerospace, and manufacturing. As the demand for accurate and efficient testing increases, the role of brands in the manufacturing of tensile testers becomes increasingly significant. This article explores the landscape of tensile tester brands and their respective factories.

The Importance of Tensile Testing

Tensile testing involves pulling a material specimen to evaluate its strength, ductility, and elasticity. The results from these tests help engineers and manufacturers make informed decisions regarding material selection and product design. As industries continue to innovate, the need for precise tensile testing equipment has grown, leading to a competitive market populated by various brands.

Key Players in the Industry

Numerous brands are well-established in the tensile tester manufacturing arena, each with unique offerings and capabilities. Some of the leading brands include

1. Instron A pioneer in the field, Instron has been manufacturing tensile testing equipment for over 75 years. Their testers are known for high precision and advanced features, catering to a wide array of industries.

2. MTS Systems Corporation Specializing in test systems and sensors, MTS is recognized for its innovative approaches to mechanical testing. Their equipment is widely used in research environments and industrial applications.

3. ZwickRoell A German manufacturer, ZwickRoell is noted for its high-quality tensile testers that offer reliability and versatility across various materials and applications.

4. Shimadzu This brand is revered for its comprehensive range of testing machines that combine advanced technology with user-friendly interfaces, making them accessible to both experienced and novice users.

5. Tinius Olsen Known for its durable testing machines, Tinius Olsen has a long history in the industry and offers a range of tensile testers suitable for a variety of material types.

These brands generally have dedicated factories where their tensile testers are designed, tested, and manufactured

. These factories often employ cutting-edge technology in both production and quality assurance processes, ensuring that each testing machine meets rigorous industry standards.brands tensile tester factories

Manufacturing Processes and Quality Control

The manufacturing of tensile testers involves several precise engineering processes. Each factory implements strict quality control measures to ensure that every machine produced delivers accurate and reliable results. The key processes include

1. Design and Engineering Utilizing advanced CAD software, engineers design tensile testers that can handle specific testing requirements. This phase also includes simulations to predict the performance of the machine under various conditions.

2. Fabrication Once designs are finalized, manufacturing begins with the fabrication of components. High-strength materials are commonly used to withstand the considerable forces exerted during testing.

3. Assembly After fabrication, components are meticulously assembled. This requires skilled technicians to integrate various parts, ensuring that all mechanical and electronic systems function correctly.

4. Testing and Calibration Before leaving the factory, each tensile tester undergoes rigorous testing to ensure precision. Calibration is performed against established standards to guarantee accuracy.

The Role of Technology in Tensile Testing

Advancements in technology have ushered in a new era for tensile testers. Modern machines increasingly incorporate digital interfaces, enabling real-time data collection and analysis. Some brands are now offering software solutions that allow users to visualize test results, generate reports, and share data seamlessly.

Additionally, the integration of artificial intelligence in testing equipment is becoming more prevalent. AI algorithms can analyze test data, predict failure modes, and provide insights that enhance the testing process's precision and efficiency.

Looking to the Future

As industries evolve and new materials are developed, the demand for advanced tensile testing equipment will continue to grow. Brands that prioritize innovation, quality, and customer support will likely thrive in this competitive landscape.

In conclusion, the world of tensile tester manufacturers is rich with brands committed to excellence and technological advancement. As these companies continue to push the boundaries of what's possible in material testing, they play a critical role in shaping the future of engineering and manufacturing. By understanding the brands behind these machines, stakeholders can make informed decisions that impact the quality and reliability of their products.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

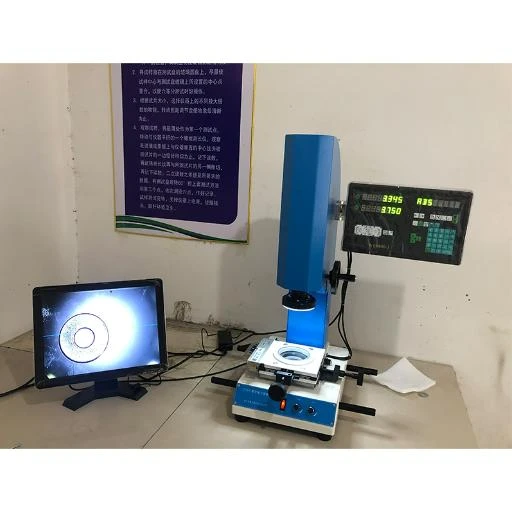

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy