brands tensile tester factories

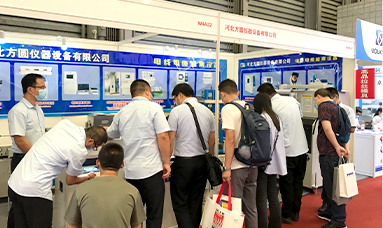

Exploring Brands and Factories of Tensile Testing Equipment

In the realm of material testing, tensile testing stands out as a fundamental method to assess the mechanical properties of various materials. Essential for industries ranging from manufacturing to construction, tensile testing machines and their associated technologies play a critical role. This article delves into the landscape of brands and factories that produce tensile testers, highlighting their innovations, capabilities, and impact on quality assurance.

Understanding Tensile Testing

Tensile testing, often referred to as tension testing, involves applying a uniaxial force to a material until it deforms or breaks. The results of this testing provide vital information on properties such as ultimate tensile strength, yield strength, elasticity, and ductility. These metrics are crucial for engineers and designers to ensure that materials can withstand the stresses they will encounter in real-world applications.

Leading Brands in Tensile Testers

Various brands have established themselves as leaders in the tensile testing market, each with unique offerings and technological advancements

. Notably, companies like Instron, MTS Systems Corporation, and ZwickRoell have emerged as key players.1. Instron With over 75 years of experience, Instron is a pioneer in materials testing equipment. Their tensile testers are renowned for precision and reliability. The company provides a wide range of machines suitable for everything from simple tensile tests to more complex applications involving fatigue testing and high-temperature conditions. Their advanced software solutions also facilitate robust data analysis.

2. MTS Systems Corporation Known for its innovation, MTS has continuously evolved its product line to meet the demands of various industries, including aerospace, automotive, and biomedical sectors. Their systems are designed to simulate real-world conditions, providing insights into how materials behave under different stresses and settings.

3. ZwickRoell A prominent name in the European market, ZwickRoell is known for its high-quality testing machines that combine accuracy with user-friendly interfaces. They focus on both standard tensile tests and specialized testing solutions, ensuring comprehensive evaluations of material properties.

brands tensile tester factories

Emerging Players and Technological Innovations

In addition to the established brands, several emerging companies are making significant contributions to the tensile testing landscape, largely through technological innovations. For instance, companies are increasingly integrating automation and digital solutions into their testing machines. Automated tensile testers not only reduce human error but also increase efficiency, allowing for high-throughput testing in laboratories.

Furthermore, the advent of smart technologies has birthed machines equipped with IoT capabilities. These testers can collect data in real-time, facilitating remote monitoring and immediate feedback. Such innovations enhance the testing processes and ensure that quality control measures are adhered to without delay.

The Role of Factories in Production

The manufacturing facilities that produce tensile testers are crucial to the entire testing ecosystem. Quality control within these factories is paramount; strict adherence to international ISO standards ensures that every machine is tested and calibrated before reaching the market. Many leading brands operate their factories with state-of-the-art technology, emphasizing precision engineering to guarantee the reliability and accuracy of their products.

Sustainability is also becoming a focus for many manufacturers. Factories are exploring environmentally friendly materials and processes to produce their machines, reflecting a growing commitment to reducing their ecological footprint. This shift is not only beneficial for the planet but also resonates with consumers who are increasingly prioritizing sustainability in their purchasing decisions.

Conclusion

The brands and factories behind tensile testing equipment embody the intersection of technology, quality, and innovation. As industries continue to evolve, so will the demand for advanced testing solutions that ensure material integrity and safety. By concentrating on precision engineering and integrating cutting-edge technology, these companies will not only meet current industry standards but also pave the way for future advancements in material testing. As we look ahead, it’s clear that the role of tensile testers in product development and quality assurance will remain indispensable.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy