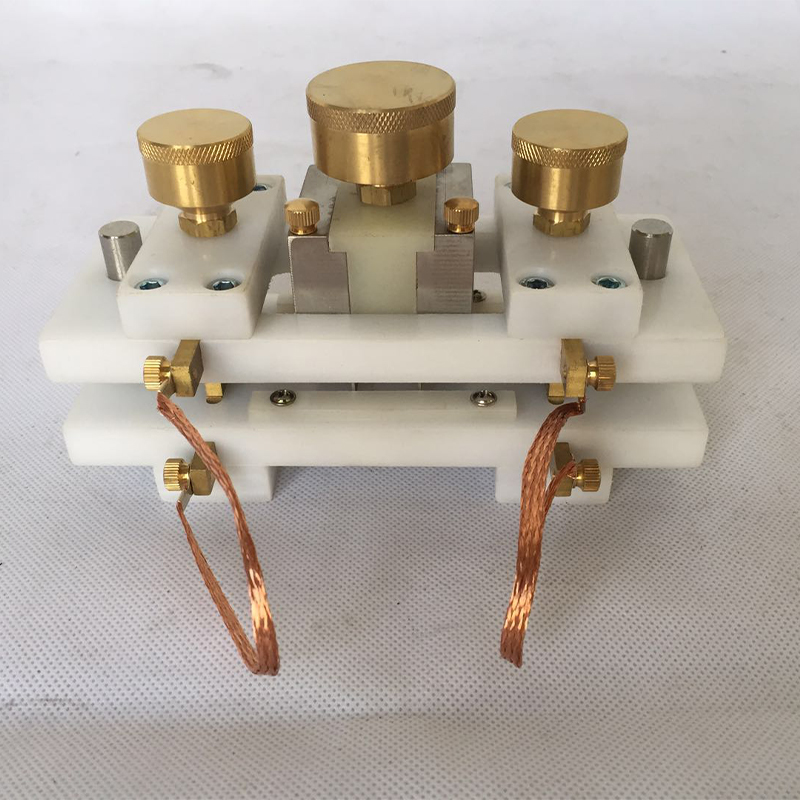

bundle cable burning test machine factories

Bundle Cable Burning Test Machine Factories Ensuring Safety and Compliance

In today’s world, the demand for electrical cables and wires continues to rise, fueled by advancements in technology and the expansion of industries like construction, automotive, and telecommunications. With this increased demand, ensuring the safety and reliability of these cables is paramount, particularly in the context of fire safety. This is where bundle cable burning test machines come into play, providing essential testing services to manufacturers. This article explores the significance of these machines, their operational principles, and the factories dedicated to producing them.

Bundle cable burning test machines are specialized devices designed to assess the flammability and fire resistance of bundled electrical cables. The process involves subjecting a group of cables, typically of the same type, to controlled burning conditions. By analyzing how these materials react under fire, manufacturers can ascertain whether their products meet international safety standards, such as those set by UL (Underwriters Laboratories) or IEC (International Electrotechnical Commission). These tests are crucial in preventing fire hazards in residential and commercial buildings, vehicles, and various electronic devices.

Factories specializing in bundle cable burning test machines are equipped with advanced technology and knowledgeable personnel who understand the nuances of fire safety testing. The design and engineering of these machines often involve extensive research and development, focusing on creating a controlled environment that mimics real-life fire scenarios. Features like adjustable temperature settings, controlled airflow, and precise measurement tools are integral to ensuring accurate and reliable testing outcomes.

bundle cable burning test machine factories

One of the key aspects of the manufacturing process in these factories is the adherence to quality control standards. Every machine produced undergoes rigorous testing to guarantee that it meets industry norms and can effectively perform its designated tasks. Factories often collaborate with certification bodies to validate the performance of their machines. This partnership not only enhances the credibility of the products but also instills confidence among manufacturers investing in the testing machines.

Additionally, the global focus on safety regulations and standards has led to an increased investment in the research and development of bundle cable burning test machines. Factories are continuously innovating, integrating cutting-edge technology such as IoT (Internet of Things) capabilities into their designs. These advancements enable remote monitoring and data collection during tests, making the analysis of results more convenient for manufacturers. As industries evolve, the flexibility and adaptability of testing machines become critical, allowing manufacturers to keep pace with changing regulations.

Furthermore, the significance of sustainable practices in manufacturing is gaining traction. Factories are now prioritizing environmentally friendly materials and efficient production methods. For instance, by using recyclable components and minimizing waste during the manufacturing process, these factories can contribute to a more sustainable future. This focus aligns with the growing demand for corporate social responsibility among consumers and industries alike.

In conclusion, bundle cable burning test machine factories play a pivotal role in ensuring the safety and reliability of electrical cables and wires. As industries continue to expand and evolve, the importance of these machines becomes increasingly essential. By investing in sophisticated testing technologies, manufacturers can not only comply with safety regulations but also enhance their product quality. Through innovation, quality control, and sustainable practices, these factories are setting the stage for safer electrical infrastructures worldwide, ultimately protecting lives and property from fire hazards. As the industry progresses, the commitment to safety will undoubtedly remain at the forefront of cable manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy