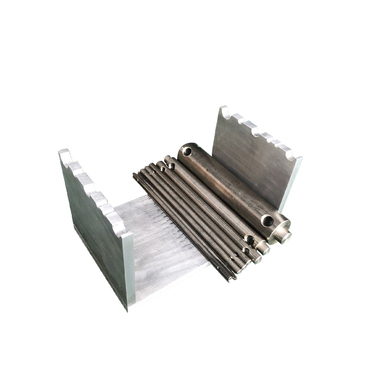

bundle cable burning test machine factory

The Importance of Bundle Cable Burning Test Machines in Manufacturing

In the world of electrical engineering and manufacturing, ensuring the safety and reliability of products is paramount. One crucial aspect of this is the testing of bundle cables, which are used in a variety of applications ranging from automotive to aerospace. The bundle cable burning test machine plays a vital role in this process, helping manufacturers assess the fire resistance and overall safety of their cable products.

Understanding Bundle Cables

Bundle cables consist of multiple conductors bundled together, often insulated by a protective sheath. These cables are common in complex systems where space is limited, such as in airplanes, cars, and industrial machinery. However, the compact nature of these bundles poses a significant risk in the event of a fire. The burning of a single cable can lead to the rapid ignition of surrounding cables, resulting in catastrophic failures. Hence, rigorous testing is essential.

The Role of Burning Test Machines

Burning test machines simulate realistic fire conditions to evaluate the performance of bundle cables. These machines are designed to expose the cables to a controlled flame while measuring critical parameters such as temperature, smoke production, and combustion behavior. By using a standardized testing method, manufacturers can obtain reliable data that reflects how their products will behave in real-life fire situations.

Key Features of Burning Test Machines

1. Controlled Environment These machines create a consistent atmosphere for testing, allowing for accurate comparisons across different types of cables.

2. Data Recording Advanced models come equipped with sensors and software that record essential data during the burning test, such as flame spread rates and toxic gas emissions.

3. Safety Precautions Given the nature of the tests, safety is a top priority. Many machines include containment chambers and fire suppression systems to mitigate risks.

4. Compliance with Standards A reputable burning test machine will adhere to international safety standards such as UL (Underwriters Laboratories), IEC (International Electrotechnical Commission), and ISO (International Organization for Standardization). This compliance is vital for manufacturers aiming to market their products globally.

bundle cable burning test machine factory

Benefits of Testing Bundle Cables

The advantages of using a bundle cable burning test machine extend beyond mere compliance. Here are several key benefits

1. Enhanced Safety By identifying vulnerabilities in cable assemblies, manufacturers can improve designs to enhance overall safety.

2. Reduced Liability Comprehensive testing helps mitigate risks that can lead to liability claims in case of accidents resulting from faulty cables.

3. Market Confidence Providing proof of rigorous fire safety testing can boost consumer confidence, making it easier for manufacturers to market their products.

4. Product Improvement The data gathered from these tests can inform research and development efforts, leading to more robust and innovative cable solutions.

Selecting a Reliable Factory

When looking to acquire a bundle cable burning test machine, it is essential to choose a reputable manufacturer. Factors to consider include the factory's experience in producing testing equipment, the quality of their machines, and post-sale support. A reliable factory will not only provide a high-quality product but also ensure that you receive adequate training and assistance during the integration and usage of the machine.

Conclusion

In conclusion, the significance of bundle cable burning test machines cannot be overstated in today's manufacturing landscape. With the increasing focus on safety and compliance, these machines are essential tools for evaluating the performance of bundle cables. Investing in a high-quality burning test machine not only enhances product safety but also builds confidence in manufacturers' commitment to quality. Ultimately, it paves the way for safer and more reliable electrical systems in various applications, safeguarding lives and property alike.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy