cable aging oven company

The Importance of Cable Aging Ovens in the Manufacturing Industry

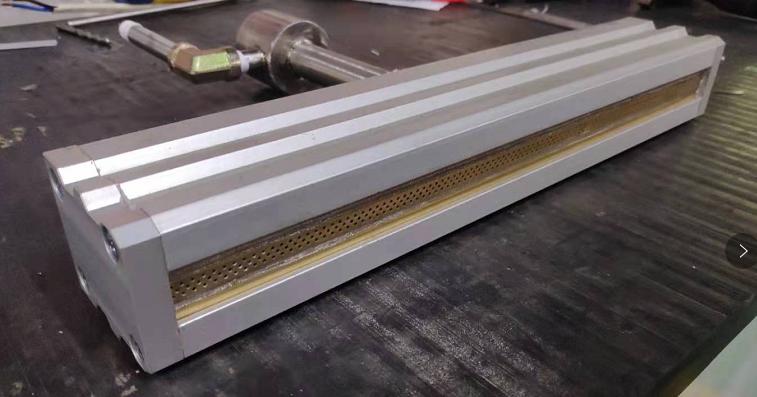

In the fast-evolving world of manufacturing, quality assurance is paramount. Among the various processes that ensure the durability and reliability of products, cable aging ovens play a critical role, especially in the production of electrical cables. These specialized chambers are designed to simulate the aging process of cables under controlled conditions, ensuring that they can withstand various environmental stresses over their intended lifespan.

The Importance of Cable Aging Ovens in the Manufacturing Industry

A cable aging oven works by recreating the conditions cables might face in real-world applications. High temperatures, varying humidity, and exposure to certain chemicals can profoundly affect the longevity and performance of electrical cables. Manufacturers rely on these ovens to expose their products to such conditions, measuring key parameters such as tensile strength, insulation resistance, and electrical performance after aging. This testing is crucial, as it provides insights into how cables will perform throughout their service life.

cable aging oven company

Investing in a cable aging oven is a strategic move for any cable manufacturing company. Firstly, it minimizes the risk of product failures, which can lead to costly recalls and damage to a company's reputation. Secondly, it aids in optimizing the production process by identifying flaws and potential weak points in the cable design before they reach the market. This proactive approach not only saves time and resources but also fosters innovation in cable technology.

Moreover, the competitive landscape of the electrical manufacturing sector demands that companies stay ahead by offering superior products. By utilizing cable aging ovens, manufacturers can provide detailed aging reports, further enhancing their product's value proposition. Customers are increasingly looking for reliable cables, especially in industries where safety and reliability are non-negotiable, such as construction, automotive, and telecommunications.

In conclusion, cable aging ovens are indispensable tools in the cable manufacturing industry. Their ability to simulate real-world aging conditions helps manufacturers ensure their products meet the highest quality standards. As the demand for reliable and durable electrical cables continues to rise, investing in the technology and processes surrounding cable aging will be key to maintaining a competitive edge. Companies that prioritize aging tests not only improve the integrity of their products but also foster greater consumer trust and satisfaction, which are essential for long-term success in this high-stakes industry.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy