cable aging oven factories

The Importance of Cable Aging Ovens in Manufacturing

In the ever-evolving landscape of manufacturing, quality control and product durability are paramount. Among various testing methodologies, the use of cable aging ovens stands out as an essential component in ensuring that cables and other insulation materials meet stringent industry standards. This article explores the significance of cable aging ovens in factories, emphasizing their role in enhancing product reliability and safety.

Cable aging ovens are specialized equipment designed to simulate the aging process of insulated cables under controlled conditions. This aging process is critical because cables, like any other product, degrade over time due to exposure to heat, moisture, and environmental stressors. Manufacturers need to ensure that their products can withstand these factors over their intended lifespan. Aging ovens accelerate this testing process by providing environments with elevated temperatures and humidity levels, thereby mimicking years of real-world wear in a fraction of the time.

The Importance of Cable Aging Ovens in Manufacturing

One of the primary goals of using cable aging ovens is to assess the long-term performance of insulation materials. Insulation is vital for preventing electrical leaks, short circuits, and catastrophic failures in electrical systems. By exposing samples of cable insulation to elevated temperatures, manufacturers can evaluate how well the materials resist thermal degradation, which can lead to the breakdown of electrical properties. This process often involves testing for changes in tensile strength, elongation, and dielectric strength, among others.

cable aging oven factories

Moreover, the data obtained from aging tests is invaluable for compliance with industry standards and regulations. Many industries, especially those related to telecommunications, automotive, and aerospace, require that cables pass specific aging tests to certify their reliability and safety. By investing in cable aging ovens, manufacturers can streamline the testing process, reduce the risk of non-compliance, and ultimately uphold their reputation in the marketplace.

In addition to regulatory compliance, manufacturers who utilize cable aging ovens can achieve significant economic benefits. By identifying potential weaknesses in cable insulation early in the production process, companies can make necessary adjustments to their designs or materials, thus reducing the likelihood of product recalls and enhancing customer satisfaction. Ultimately, investing in the aging oven not only saves resources but also instills confidence among end-users regarding the quality of their products.

Finally, the implementation of cable aging ovens in factories demonstrates a commitment to research and development. The results derived from aging tests can feed into the innovation of new materials and technologies, addressing the evolving demands of electrical applications. As industries increasingly rely on advanced cables for performance and safety, the importance of rigorous testing becomes all the more apparent.

In conclusion, cable aging ovens are a foundational component of quality assurance in cable manufacturing. By enabling efficient aging tests, these ovens help ensure the reliability, compliance, and overall performance of cable products. As the demand for high-quality, durable electrical components continues to grow, the role of cable aging ovens in factories will remain critical, shaping the future of manufacturing in this essential sector.

-

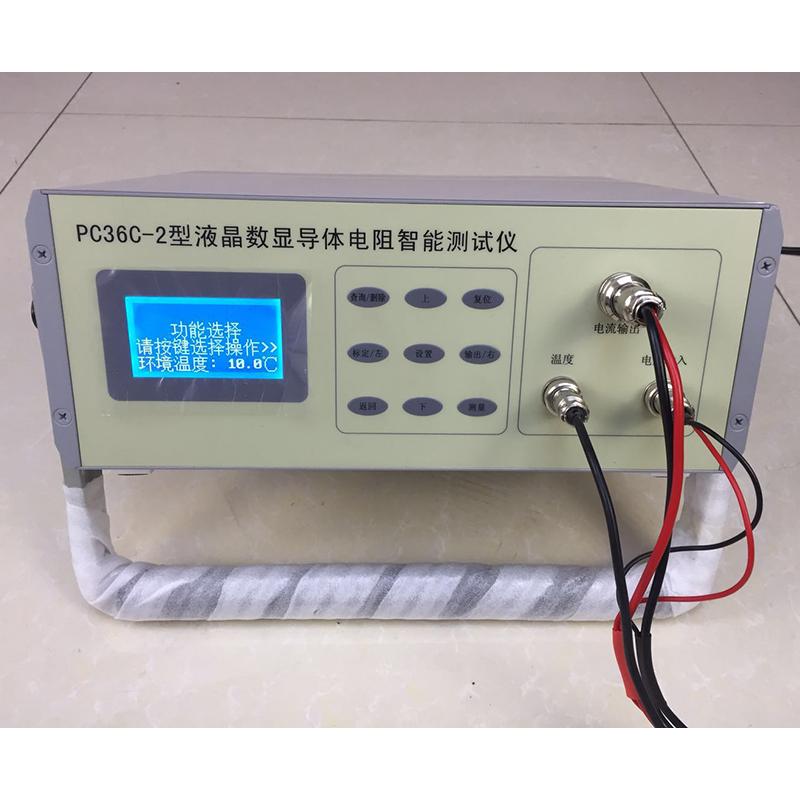

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy