Cable Flexibility Testing Apparatus for Optimal Performance and Durability Evaluation

The Importance of Cable Bending Testers in Quality Assurance

In today’s technology-driven world, cables play a crucial role in the operation of electronic devices, machinery, and systems. Whether it’s power supply cables, data transmission lines, or fiber optic cables, ensuring their reliability and durability is of utmost importance. This is where cable bending testers come into play, offering a vital means of testing and ensuring the longevity of cables in various applications.

What is a Cable Bending Tester?

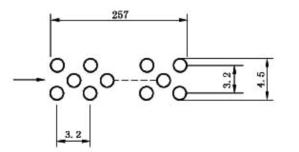

A cable bending tester is a specialized piece of equipment designed to simulate the bending and flexing that cables undergo during normal operation. By subjecting cables to repeated bending movements, these testers evaluate how well they can withstand stress without degrading or failing. This process is critical in determining the mechanical and electrical properties of cables, and it helps to predict their lifespan in practical applications.

The Testing Process

The testing process typically involves placing the cable within a frame that can mimic the bending motions it would experience in real-world scenarios. The test may apply specified angles of bending and cycles, often guided by international standards such as IEC 60227 for power cables or ISO 10462 for fiber optics. The goal is to assess not only the physical integrity of the cable jacket but also the performance of its internal conductors.

During the test, various parameters are monitored, including electrical resistance, signal integrity, and the cable's ability to return to its original form after bending. Sensors and software are often employed to provide precise measurements and data analytics, allowing manufacturers to make informed decisions about cable design and materials.

Applications Across Industries

cable bending tester

Cable bending testers are utilized across numerous industries, including telecommunications, automotive, aerospace, and renewable energy. In telecommunications, for example, cables must be able to flex during installation and use without compromising signal quality. Similarly, in the automotive sector, cables are subjected to relentless movement due to vibrations and changes in temperature, necessitating rigorous testing to ensure safety and reliability.

In the renewable energy sector, particularly with the rise of electric vehicles and solar power systems, the demand for durable cables is growing. Testing these cables for bending and flex fatigue is essential to minimize the risk of failures that could lead to costly downtime or safety hazards.

Ensuring Quality and Compliance

Manufacturers must adhere to strict quality assurance standards, and using cable bending testers is a key part of this process. By performing these tests, companies can ensure that their products not only meet regulatory requirements but also exceed customer expectations for performance and reliability. This assurance builds trust with consumers and partners, ultimately enhancing brand reputation in competitive markets.

In addition to quality assurance, data collected from cable bending tests can drive innovation. Insights gained can lead to the development of new materials and designs that offer enhanced flexibility and strength, catering to the evolving needs of the market.

Conclusion

The cable bending tester is an indispensable tool in the realm of cable manufacturing and testing. By simulating real-world bending scenarios, it provides critical insights that help ensure the durability and effectiveness of cables across a myriad of applications. As industries continue to evolve and demand higher standards for performance, the importance of cable bending testers will only increase, paving the way for safer and more reliable technology in our everyday lives. Investing in proper testing equipment not only protects manufacturers but also contributes to the overall success and safety of the products they deliver.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy