Cable Heat Pressure Testing Manufacturing Facilities Overview and Insights

The Importance of Cable Heat Pressure Test Facilities

In the modern electrical and telecommunications industries, the reliability of cables is paramount. Cables are the lifelines that transmit power and data across vast distances, connecting cities and industries. Given their critical role, it is essential that these cables meet strict safety and performance standards. One of the most effective ways to ensure cable quality is through heat pressure testing in specialized factories.

Cable heat pressure testing is a systematic method used to evaluate the integrity and performance capabilities of cables under extreme conditions. The test simulates real-world environmental stresses that cables might encounter during their lifecycle, including heat, pressure, and potential mechanical impact. By conducting these tests, manufacturers can predict how well a cable will perform in actual use, thereby mitigating risks associated with cable failures.

The Testing Process

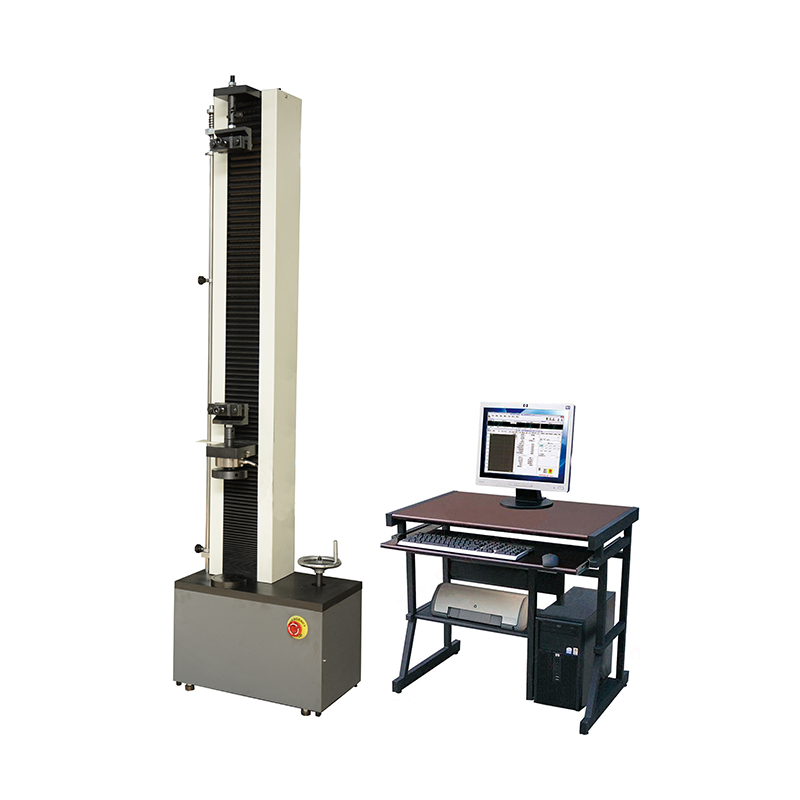

The heat pressure test is performed in factories equipped with advanced testing machinery that can replicate high temperature and pressure environments. The process typically involves subjecting cable samples to elevated temperatures while applying pressure to assess how well they withstand heat over prolonged periods. The tests may also include rapid temperature cycling, which simulates conditions that cables might face in outdoor or industrial settings.

The results from these tests provide crucial data on various attributes, including thermal stability, electrical insulation integrity, and mechanical strength. If a cable can endure these extreme conditions without degradation, it indicates high durability and reliability. Such assurances are vital, especially in sectors like energy transmission and data communications, where cable failures can lead to significant downtime, operational disruptions, and even safety hazards.

Industry Standards and Compliance

cable heat pressure test factories

Cable manufacturers are required to comply with industry standards set forth by organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL). These standards dictate the protocols and performance criteria that cables must meet to be deemed safe and effective for consumer and industrial use. A certified testing facility equipped for heat pressure testing ensures that manufacturers can meet these stringent guidelines.

Furthermore, independent testing facilities that specialize in cable heat pressure testing play a crucial role in the certification process. These third-party evaluations help establish credibility and consumer trust in cable products. By investing in comprehensive testing, manufacturers can avoid costly recalls and reputational damage associated with failed products in the market.

Economic Impact

The implications of rigorous heat pressure testing extend beyond safety; they also have economic consequences. High-quality cables result in fewer failures and longer service life, ultimately leading to cost savings for businesses. Investing in proper testing infrastructure can reduce warranty claims and enhance customer satisfaction. In a highly competitive market, where consumers are increasingly aware of safety standards, companies can differentiate themselves by emphasizing their commitment to quality assurance through rigorous testing processes.

Conclusion

In conclusion, cable heat pressure testing facilities are a cornerstone of quality assurance in the cable manufacturing industry. Through systematic evaluations under simulated conditions, these facilities help manufacturers produce reliable, safe, and durable cables. This not only complies with industry standards but also fosters consumer trust, reduces the risk of failures, and bolsters the economic viability of businesses. As technology continues to advance, the importance of these testing processes will only become more pronounced, ensuring that our electrical and telecommunications infrastructures remain robust and dependable.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy