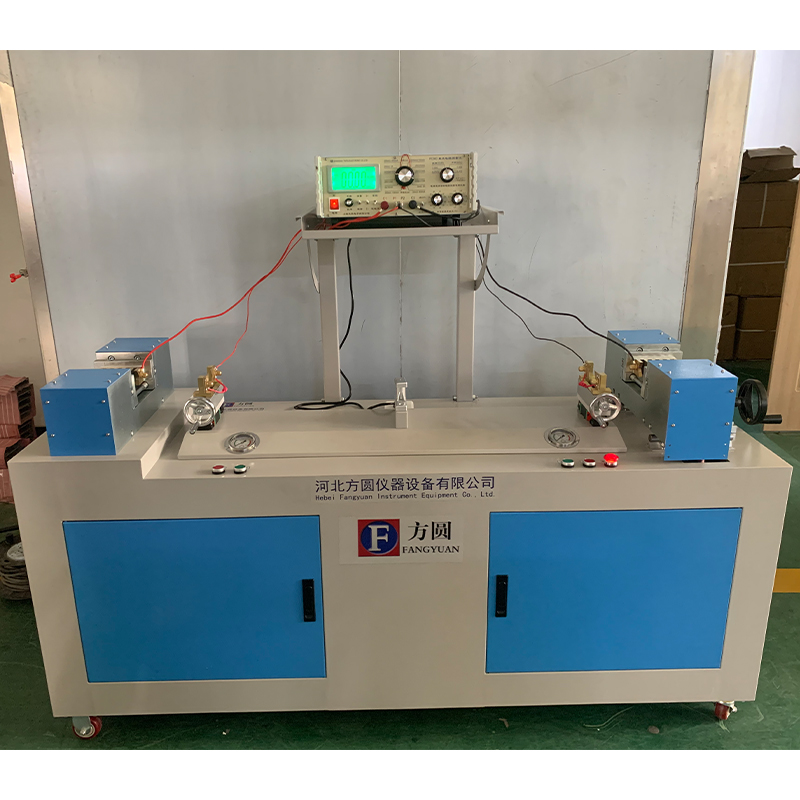

cable insulation cut machine supplier

Cable Insulation Cut Machine Supplier Revolutionizing the Wiring Industry

In the ever-evolving landscape of the electrical and telecommunication sectors, the need for precision and efficiency has never been greater. One critical aspect of this industry is the processing of cable insulation, an essential step in ensuring that products meet safety and performance standards. Enter the cable insulation cut machine—an innovative solution that is gaining traction among manufacturers and suppliers alike.

A cable insulation cut machine is specifically designed to remove the outer shielding of wires and cables, allowing for the required electrical connections to be made safely and efficiently. These machines offer remarkable benefits that can significantly improve production lines. For instance, they enhance accuracy and minimize wastage by ensuring that each cut is made to exact specifications, reducing the likelihood of errors that may occur with manual processes.

One of the primary advantages of using a cable insulation cut machine is the increase in productivity. Traditional methods, which often involve manual cutting or stripping, can be time-consuming and labor-intensive. In contrast, modern insulation cutting machines can process multiple cables simultaneously, drastically reducing the time needed to prepare wires for assembly. This improvement not only boosts output rates but also allows manufacturers to meet tight deadlines and fulfill larger orders.

cable insulation cut machine supplier

Furthermore, the reliability of these machines cannot be overstated. With advancements in technology, cable insulation cut machines now come equipped with features such as programmable settings, digital displays, and automated safety mechanisms. These enhancements ensure that operators can achieve consistent results, thus maintaining high-quality standards throughout the production process.

When selecting a cable insulation cut machine supplier, it is crucial to consider several factors. A reputable supplier should provide not only high-quality machines but also exceptional customer service and support. This includes installation assistance, comprehensive training for operators, and ongoing maintenance services. Companies must seek out suppliers that prioritize their clients' needs and understand the intricacies of the cable manufacturing process.

Moreover, suppliers that offer a range of customization options for their machines can provide businesses with solutions that cater specifically to their operational requirements. Whether dealing with various cable sizes, insulation materials, or production volumes, having a machine that can adapt to different needs can provide a significant competitive edge.

In conclusion, the emergence of cable insulation cut machines represents a significant advancement in the wiring industry. With their ability to enhance accuracy, increase productivity, and ensure reliability, these machines are indispensable tools for manufacturers looking to improve their processes. By partnering with a trusted supplier who understands the importance of quality and support, businesses can unlock the full potential of their operations, paving the way for greater success in a fast-paced market. As the industry continues to grow and evolve, the role of these machines will undoubtedly become even more pivotal, transforming the way companies handle cable production for years to come.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy