cable sheath cut machine exporters

The Rise of Cable Sheath Cut Machine Exporters A Global Perspective

In recent years, the demand for efficient manufacturing processes in the cable and wire industry has surged, leading to an increased interest in specialized equipment such as cable sheath cut machines. These machines are essential for the precise cutting of cable sheaths, thus facilitating enhanced productivity and quality in the production line. As industries worldwide seek to optimize their operations, cable sheath cut machine exporters have witnessed significant growth, impacting the global market landscape.

Cable sheath cut machines serve a vital role in various applications, including telecommunications, electronics, automotive, and construction. These machines are designed to handle different types of cables, ensuring clean and accurate cuts to enhance the performance of cable assemblies. With advancements in technology, modern cutting machines are equipped with features like automatic feed systems, digital controls, and safety mechanisms, making them a preferred choice for manufacturers.

Exporters of cable sheath cut machines are expanding their footprint across different regions, driven by the growing industrialization and investment in infrastructure projects worldwide. Countries such as Germany, the United States, Japan, and China are leading the way in manufacturing and exporting these machines, capitalizing on their advanced engineering capabilities and established supply chains. Moreover, emerging markets in Southeast Asia, Eastern Europe, and Africa are gradually becoming key destinations for cable sheath machine exports as their respective industries grow.

cable sheath cut machine exporters

One of the key factors contributing to the increasing demand for cable sheath cut machines is the shift towards automation in manufacturing. Companies are recognizing the benefits of investing in automated solutions to reduce manual labor, minimize human errors, and improve overall efficiency. Consequently, exporters are enhancing their product offerings to include fully automated systems that cater to the diverse needs of manufacturers, thus positioning themselves competitively in the global market.

Sustainability is another pivotal trend influencing the cable industry. With a growing emphasis on eco-friendly practices, manufacturers are seeking machines that minimize waste and energy consumption. Exporters are responding by incorporating sustainable technologies and materials in their machine designs, appealing to environmentally conscious businesses.

However, cable sheath cut machine exporters also face challenges in the competitive landscape. The rise of domestic manufacturers in developing countries, fluctuating raw material prices, and the need for continuous innovation require exporters to stay agile and responsive to changing market demands.

In conclusion, the export of cable sheath cut machines represents a dynamic segment of the manufacturing equipment market, driven by advancements in technology, the push for automation, and increasing global infrastructure projects. As industries continue to evolve, exporters must adapt and innovate to maintain their competitive edge and meet the diverse needs of their customers worldwide. The future looks promising for cable sheath cut machine exporters as they play a crucial role in shaping the efficiency of cable manufacturing processes globally.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

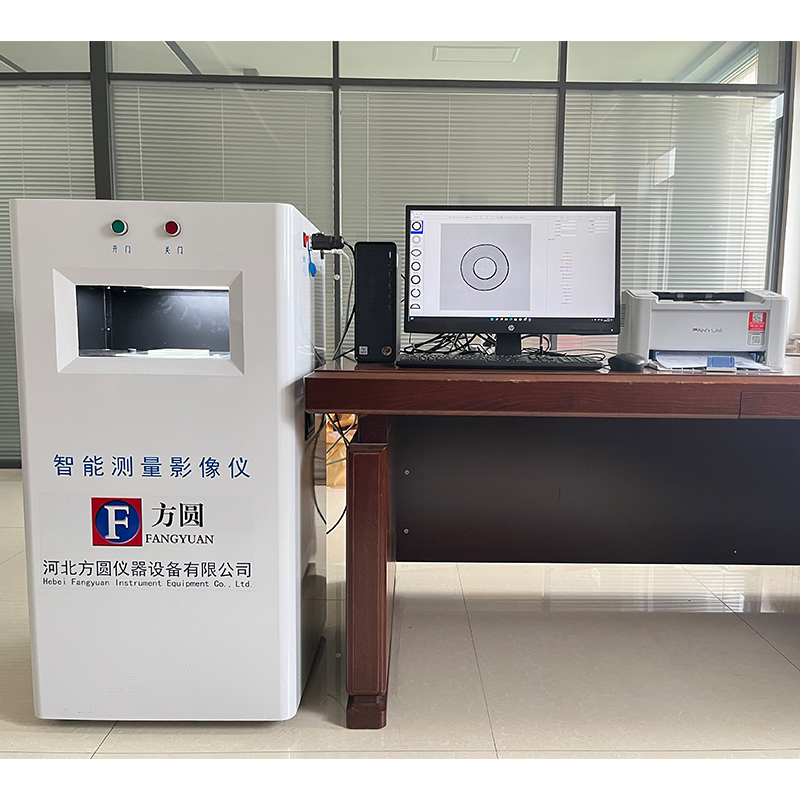

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy