cable smoke density test chamber company

Understanding Cable Smoke Density Test Chambers A Crucial Component for Safety Standards

In the modern world, safety standards in materials used for electrical cables have become increasingly stringent. One of the key components in ensuring compliance with these safety standards is the cable smoke density test chamber. These specialized chambers are designed to evaluate the smoke density produced by burning cables, which is vital for assessing the fire safety of electrical installations.

The importance of smoke density testing cannot be overstated. When cables are subjected to high temperatures or flames, they can emit smoke that poses serious health risks to individuals in proximity, as well as complicating rescue operations during emergencies. High smoke density can lead to reduced visibility and respiratory issues, making the evaluation of this characteristic pivotal in various applications, from residential buildings to large commercial facilities.

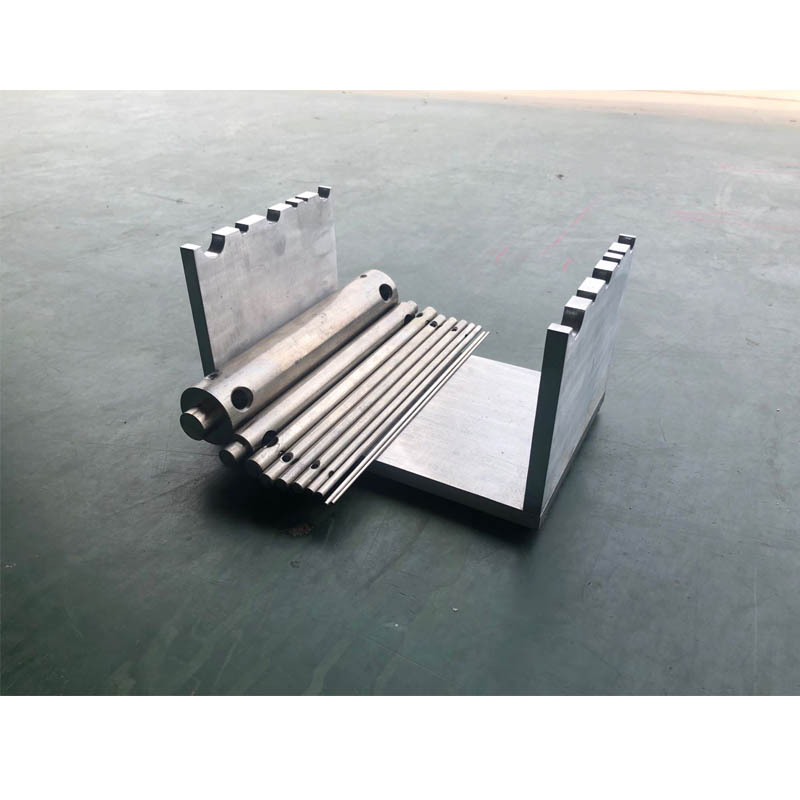

A cable smoke density test chamber is engineered to create controlled conditions that simulate real fire scenarios. These chambers are equipped with precise instrumentation to measure the quantity of smoke produced during the combustion of materials. The test typically involves exposing cables to a flame while measuring the light obscuration of the smoke that is generated. This measurement gives an accurate representation of the smoke density, which can then be compared against established safety standards.

Several companies specialize in the manufacturing of smoke density test chambers, each incorporating innovative technologies to enhance accuracy and efficiency

. These companies are committed to providing reliable testing solutions, ensuring that their equipment meets international standards such as ISO 5659, governing the smoke generation of materials.cable smoke density test chamber company

In addition to smoke density testing, these chambers often facilitate a variety of other tests to provide a comprehensive assessment of cable materials. This includes testing for flame spread, toxicity of smoke, and the release of corrosive gases. By evaluating these properties, manufacturers can ensure that their products are safe for use in any environment, significantly reducing the risk of fire hazards.

The advancements in testing technology also contribute to the overall development of safer materials. With increased awareness of fire safety and regulations tightening, manufacturers are encouraged to innovate and improve their materials continually. This push not only benefits manufacturers seeking compliance but also enhances the safety of end-users.

Furthermore, regulatory bodies and insurance companies increasingly require rigorous testing processes to minimize risks associated with cable fires. As a result, having access to high-quality smoke density test chambers becomes an essential factor for companies striving to meet these evolving standards.

In summary, the role of cable smoke density test chambers in ensuring the fire safety of electrical installations is imperative. With a focus on accurate testing, compliance with international standards, and continuous innovations, these test chambers help manufacturers produce safer cables, ultimately protecting lives and property. As industries evolve and safety becomes a priority, the significance of these testing solutions will continue to grow, reinforcing the commitment to a safer, more secure environment for all.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy