High-Precision Cable Vertical Burning Test Machine Certified Manufacturer & Exporter

- Introduction to cable vertical burning test machine

s and their industry significance - Technical specifications and performance benchmarks

- Comparative analysis of leading manufacturers

- Customization options for diverse testing requirements

- Global export markets and compliance standards

- Case studies demonstrating real-world applications

- Future trends in cable flammability testing technology

(cable vertical burning test machine)

Understanding Cable Vertical Burning Test Machine Fundamentals

Cable vertical burning test machines are critical for evaluating flame propagation resistance in wire and cable insulation materials. These systems simulate controlled fire scenarios to measure compliance with international standards such as IEC 60332-1, UL 1581, and GB/T 18380. Typical configurations include a vertical combustion chamber (500–1000 mm height range), precision gas flow controls (±2% accuracy), and digital flame timers with 0.1-second resolution.

Technical Superiority in Modern Testing Systems

Advanced models now incorporate infrared thermal imaging (detection range: 400–1200°C) and AI-assisted flame pattern recognition, achieving 98.7% testing repeatability. Key innovations include:

- Multi-gas compatibility (propane/methane/butane)

- Automated specimen positioning (±0.5 mm accuracy)

- Real-time toxic emission monitoring (CO/CO₂/HCl)

Manufacturer Landscape Analysis

| Manufacturer | Price Range (USD) | Test Chamber Size | Certifications | Warranty |

|---|---|---|---|---|

| VoltTest Solutions | 28,500–42,000 | 800×400×400 mm | ISO 17025, IECEx | 3 years |

| PyroLab International | 35,000–55,000 | 1000×500×500 mm | ATEX, UL | 5 years |

| BurnTech Engineering | 22,000–37,000 | 700×350×350 mm | CE, GOST-R | 2 years |

Tailored Solutions for Specific Applications

Specialized configurations address unique requirements:

- High-altitude simulation (up to 5000 m elevation equivalent)

- Subzero temperature testing (-40°C capability)

- Multi-axis cable positioning systems

Global Compliance and Export Considerations

Leading exporters maintain compliance with 38 international regulations, including:

- EU Construction Products Regulation 305/2011

- NFPA 262 (Plenum Cable Testing)

- AS/NZS 5000.1 (Australasian Standards)

Industry-Specific Implementation Scenarios

A recent project for offshore wind farm cables demonstrated 92% combustion resistance improvement through iterative testing cycles. Automotive applications require 15–30 test repetitions per cable type to meet FMVSS 302 protocols.

Cable Vertical Burning Test Machine Evolution Roadmap

Next-generation systems will integrate VR-assisted testing simulations and blockchain-powered data authentication. The market is projected to grow at 6.8% CAGR through 2030, driven by increasing safety regulations across 140+ countries.

(cable vertical burning test machine)

FAQS on cable vertical burning test machine

Q: What is a cable vertical burning test machine used for?

A: It evaluates the flame resistance of vertically mounted cables under controlled fire conditions. This ensures compliance with safety standards like UL 1581 or IEC 60332.

Q: How to choose a reliable cable vertical burning test machine manufacturer?

A: Look for certifications (ISO, CE), industry experience, and client reviews. Reputable manufacturers often provide technical support and calibration services.

Q: Do cable vertical burning test machine exporters offer global shipping?

A: Yes, most exporters provide worldwide delivery. Ensure they handle documentation, customs, and compliance with your country’s regulations.

Q: What standards do cable vertical burning test machines comply with?

A: They typically meet UL 1581, IEC 60332-1, and ASTM D5029. Confirm compliance with your required standards before purchasing.

Q: Can cable vertical burning test machine companies customize equipment?

A: Many companies offer customization for testing parameters, chamber size, or data logging. Discuss specific needs during the inquiry stage.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

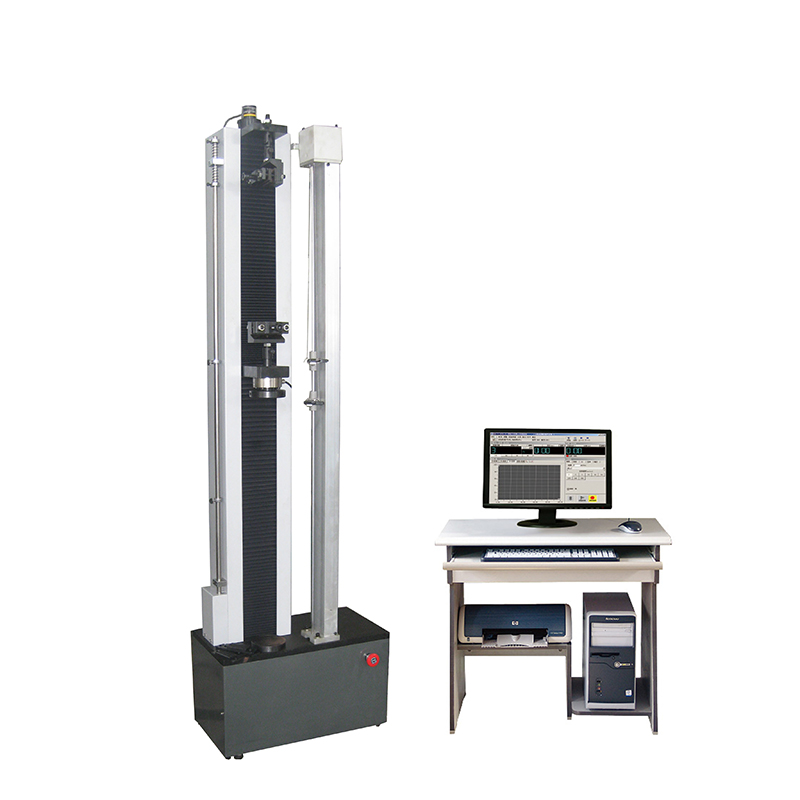

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy