cable bending tester

Understanding Cable Bending Testers Importance and Applications

In today’s fast-paced world of technology, the integrity of cables and connectors plays a crucial role in the performance of electronic devices. Ensuring that these components can withstand stress and maintain functionality is paramount, which is where cable bending testers come into play. These specialized devices are designed to simulate the bending and flexing that cables undergo during everyday use, ensuring that they meet rigorous durability and reliability standards.

A cable bending tester typically consists of a framework that holds the cable in place while subjecting it to specified bending angles and cycles

. This process helps identify potential weaknesses in the material or construction of the cable, such as insulation failure, conductor breakage, or connector loosening. By replicating real-world conditions, manufacturers can evaluate their products' lifespan and performance in a controlled environment.The importance of cable bending testers cannot be overstated. As technology advances, cables are becoming increasingly complex and multifunctional. They are used in various industries, from telecommunications to automotive and medical devices. Each application has its own set of stresses and requirements, making the need for comprehensive testing paramount. A robust cable bending tester helps ensure that cables are not only compliant with industry standards but also meet the specific needs of their intended applications.

cable bending tester

Moreover, the results obtained from cable bending tests are invaluable for manufacturers. They provide critical data that can be used to improve product designs and materials, leading to enhanced performance and durability. By identifying issues early in the development process, manufacturers can save time and resources, ultimately leading to a more reliable product on the market.

In addition to performance testing, cable bending testers also play a role in quality control during manufacturing. By integrating testing protocols into the production process, manufacturers can ensure that every cable produced meets the necessary quality standards. This step is crucial for maintaining brand reputation and customer satisfaction, as failures in cable performance can lead to significant operational failures and financial losses.

In conclusion, cable bending testers are essential tools in the modern electronics industry. By simulating real-world conditions and providing valuable insights into cable performance, they help ensure that products are durable, reliable, and ready to meet the demands of consumers. As technology continues to evolve, the importance of these testing devices will only grow, underscoring their role in fostering innovation and quality in cable manufacturing.

-

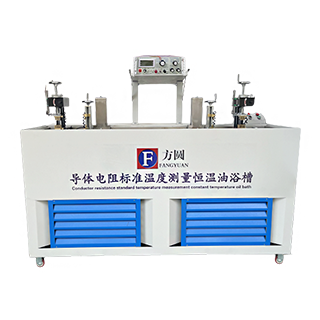

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy