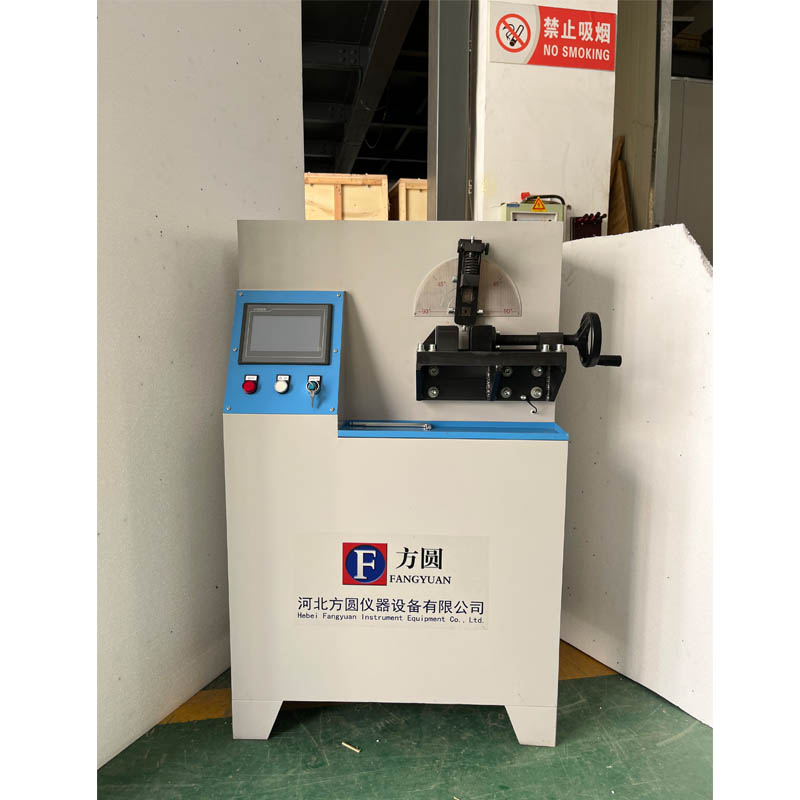

cable bending tester manufacturer

Cable Bending Tester Manufacturer Ensuring Quality and Durability in Cable Production

In today's fast-paced technological world, the importance of quality assurance in manufacturing cannot be overstated. As industries continue to evolve and innovate, the demand for reliable and durable products has surged. One critical aspect of this process is the testing of cables, especially given their extensive use in various applications, from telecommunications to automotive systems. Understanding the significance of this testing, many manufacturers are now investing in cable bending testers to ensure the functionality and longevity of their products. This article explores the role of cable bending tester manufacturers in this crucial segment of quality control.

Understanding Cable Bending Testers

A cable bending tester is a specialized piece of equipment designed to evaluate the flexibility and durability of cables under bending stresses. These testers simulate real-world conditions that cables are likely to face throughout their operational life. By subjecting cables to repetitive bending cycles, manufacturers can identify potential weaknesses and areas of failure, helping to ensure their products meet industry standards and customer expectations.

The Manufacturing Process

Cable bending tester manufacturers focus on creating superior testing machines that can mimic various bending scenarios. This includes adjusting angles, bending radii, and load conditions tailored to the specific type of cable being tested. The manufacturing process typically involves a combination of mechanical engineering, software development, and electronic design to ensure a reliable, multifaceted testing solution.

Key Features of High-Quality Cable Bending Testers

1. Precision Engineering Renowned manufacturers emphasize precise engineering in their designs, ensuring that every aspect of the machine operates seamlessly. This includes high-quality materials that endure the physical stresses of repeated testing.

2. Versatility A reliable cable bending tester should accommodate various cable types, including power cables, communication cables, and optical fibers. Top manufacturers ensure that their machines offer adaptable testing capabilities to meet diverse industry needs.

cable bending tester manufacturer

3. User-Friendly Interface Modern cable bending testers come equipped with intuitive software interfaces that allow operators to easily configure tests, monitor progress, and analyze results. This enhances user experience and reduces the likelihood of operator error.

4. Real-Time Data Logging Advanced testing machines provide the ability to log data in real-time, allowing manufacturers to track performance over time. This feature supports detailed analysis and can help refine manufacturing processes in future iterations.

5. Compliance with Standards Reputable cable bending tester manufacturers design their machines to comply with industry standards, such as IEC and UL certifications. Compliance ensures that manufacturers can produce cables that are safe and reliable, ultimately protecting consumers and businesses alike.

Benefits of Investing in Cable Bending Testers

Investing in high-quality cable bending testers can drastically improve manufacturing processes. By identifying weaknesses early in production, manufacturers can significantly reduce the risk of product failures in the field. This not only leads to lower warranty claims and repair costs but also enhances customer satisfaction and brand reputation.

Moreover, the comprehensive data generated during testing can inform design improvements in future products, fostering a culture of continuous enhancement. With the growing emphasis on sustainability and longevity, manufacturers that leverage advanced testing equipment will be better positioned in a competitive market.

Conclusion

As industries increasingly prioritize quality and reliability, the role of cable bending tester manufacturers has become more critical than ever. By investing in advanced testing solutions, manufacturers can ensure their cables are not only functional but also durable and safe for end-users. The commitment to quality control in cable production ultimately leads to increased consumer trust and loyalty, which is invaluable in today’s rapidly evolving marketplace. As we move forward, it is imperative for manufacturers to embrace the technology and methodologies offered by cable bending tester manufacturers to stay ahead in the game.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy