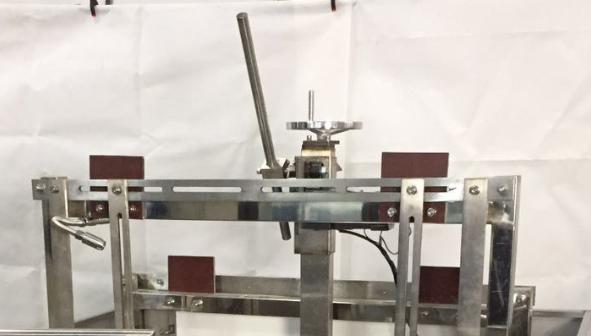

cable bending test machine

The Importance of Cable Bending Test Machines in Quality Assurance

In the modern world where technology and connectivity are paramount, the integrity of electrical cables is critical. Ensuring that cables can withstand various mechanical stresses is essential for their longevity and functionality, especially in demanding environments. One of the key tools used in this quality assurance process is the cable bending test machine.

Cable bending test machines are specifically designed to simulate the various bending and flexing conditions that cables encounter in real-world applications. These machines rigorously assess the durability and flexibility of cables by applying controlled bending cycles under specific conditions. The primary objective is to determine how well the cables can endure repeated bending without compromising their performance or structural integrity.

The importance of these machines cannot be overstated in industries ranging from telecommunications to automotive. For instance, in telecommunications, cables are often subjected to intricate routing and can experience stress due to environmental factors. A bending test machine evaluates how well cables can perform under these demanding conditions, thus ensuring that they maintain signal integrity and resist damage over time.

cable bending test machine

In addition to functional performance, cable bending test machines play a vital role in compliance with industry standards. Regulatory bodies establish stringent guidelines for cable manufacturers to ensure safety and reliability. By using bending test machines, manufacturers can verify that their products meet these standards, which is crucial for attaining necessary certifications and maintaining market trust.

The procedure typically involves a sample cable being mounted on the test machine, which is then programmed to perform a series of bending cycles at specified angles and frequencies. The test duration can vary but is often set to simulate years of typical use in a matter of hours or days. As the tests are performed, the machine records data regarding the cable's performance, allowing engineers to analyze any degradation or failure points.

Moreover, advancements in technology have enhanced the capabilities of cable bending test machines. Modern machines are equipped with sophisticated software that can provide real-time monitoring and comprehensive reporting. This not only improves accuracy but also enables manufacturers to make data-driven decisions regarding design improvements and material choices.

In conclusion, the cable bending test machine is an indispensable tool for manufacturers aiming to produce high-quality, reliable electrical cables. By simulating the stresses that cables will face in everyday applications, these machines ensure that products are both safe and effective. As technology continues to evolve and the demand for more robust cables grows, the role of bending test machines will only become more significant in maintaining industry standards and consumer trust. Investing in quality testing is not just about compliance; it is about commitment to excellence in a world increasingly reliant on connectivity.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy