Cable Flexibility Testing Equipment Manufacturers for Quality Assurance Solutions

Selecting the Right Cable Bend Test Machine Suppliers

When it comes to ensuring the durability and reliability of cables, especially in various industrial applications, one critical testing method stands out the cable bend test. This testing process not only evaluates the flexibility of the cables but also assesses their performance under repeated bending conditions. As a result, selecting the right cable bend test machine and its suppliers becomes essential for manufacturers and quality control personnel. This article will delve into the importance of cable bend test machines, the criteria for selecting suppliers, and the benefits of working with reputable providers.

The Importance of Cable Bend Testing

Cable bend testing simulates the conditions that cables will encounter in real-world applications. Whether for power distribution, telecommunications, or data transmission, cables must maintain their integrity, electrical performance, and mechanical strength under various conditions. The bend test helps identify potential weaknesses, which can lead to failures in the field if not addressed.

During the cable bend test, cables undergo a series of bending cycles, subjected to specific radii and angles to simulate actual operational scenarios. The test is crucial for manufacturers to ensure that their products meet industry standards and customer expectations. For consumers, a well-tested cable often translates to improved performance, longevity, and lower chances of failure.

Criteria for Selecting Cable Bend Test Machine Suppliers

1. Quality and Compliance When selecting a supplier, it is crucial to ensure that the cable bend test machines are manufactured in compliance with industry standards. Look for suppliers that adhere to international standards such as IEC, UL, or ISO. Quality certifications are indicators of a supplier’s commitment to excellence and reliability.

2. Machine Features and Specifications Different applications may have varying requirements when it comes to testing. It's essential to assess the features and specifications of the machines offered by suppliers. Consider aspects such as maximum cable diameter, bending radius, testing speed, and control systems. More advanced machines may offer automated controls, data logging features, and customizable testing parameters.

3. Supplier Experience and Reputation A supplier with years of experience in the cable testing industry is likely to provide better customer service and technical support. Research suppliers' market presence, customer reviews, and case studies to gauge their reputation. Experienced suppliers can often provide insights and recommendations tailored to specific needs.

cable bend test machine suppliers

4. After-Sales Support and Maintenance A good supplier does not just sell equipment; they provide ongoing support and maintenance. Ensure that the supplier offers comprehensive after-sales support, including installation, training, spare parts availability, and maintenance services. This support is invaluable for minimizing downtime and ensuring the continuous operation of testing equipment.

5. Cost and Value Proposition While price should not be the sole consideration, it is an essential factor. Evaluate the overall value proposition based on machine features, quality, lifespan, and support offered. Sometimes, spending a little more upfront can lead to significant savings in the long run through improved reliability and reduced maintenance costs.

Benefits of Working with Reputable Suppliers

Partnering with reputable cable bend test machine suppliers provides a range of benefits

- Reliability High-quality machines from established suppliers are less prone to malfunction or inaccuracies, which translates to reliable testing results. - Innovation Reputable suppliers often invest in research and development, providing cutting-edge technology that keeps you competitive in the market. - Customized Solutions Established suppliers typically have the resources to offer tailored solutions that meet specific testing needs, ensuring optimal performance.

- Strong Relationships Building long-term relationships with suppliers can lead to customized service agreements, priority access to new technology, and better pricing arrangements.

Conclusion

In conclusion, the importance of cable bend testing in ensuring product reliability cannot be overstated. Selecting the right machine and supplier is crucial to achieving high testing standards. By considering factors like compliance, features, reputation, support, and value, manufacturers can make informed choices that enhance their testing capabilities. Investing in quality suppliers ensures that companies not only meet industry standards but also gain a competitive edge in the marketplace.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

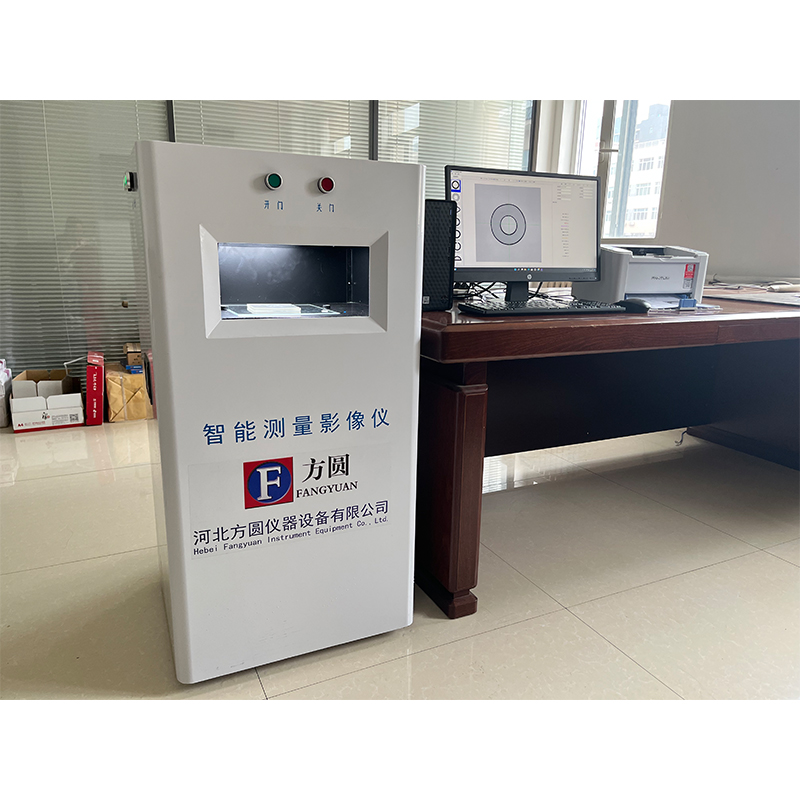

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy