Cable Bundle Fire Testing Equipment Suppliers and Manufacturers Overview

Cable Bunched Burning Test Machine Manufacturers Ensuring Safety and Compliance

In the realm of electrical engineering and safety, the importance of rigorous testing cannot be overstated. Among the various tests conducted to ensure the safety and reliability of electrical cables, the cable bunched burning test stands out as a critical measure. This test evaluates how bundled cables behave under fire conditions, providing valuable insights into their fire resistance and overall safety. Consequently, the role of manufacturers of cable bunched burning test machines plays a crucial part in this safety assurance process.

Understanding the Cable Bunched Burning Test

The cable bunched burning test is designed to simulate real-world fire scenarios where multiple cables are subjected to flame exposure. The objective is to ascertain how the cables will perform when exposed to high temperatures, whether they will ignite, and what toll they take on the surrounding environment. This testing is paramount, not just for compliance with international safety standards but also to safeguard lives and property.

Conducted typically in controlled environments, the test involves grouping several cables together and exposing them to a flame for a specified duration. Factors measured during this test include the flames' propagation rate, smoke production, and the potential for toxic gases to be emitted. The end results help manufacturers determine the fire performance of their products, ensuring that they meet the necessary safety regulations.

The Role of Manufacturers

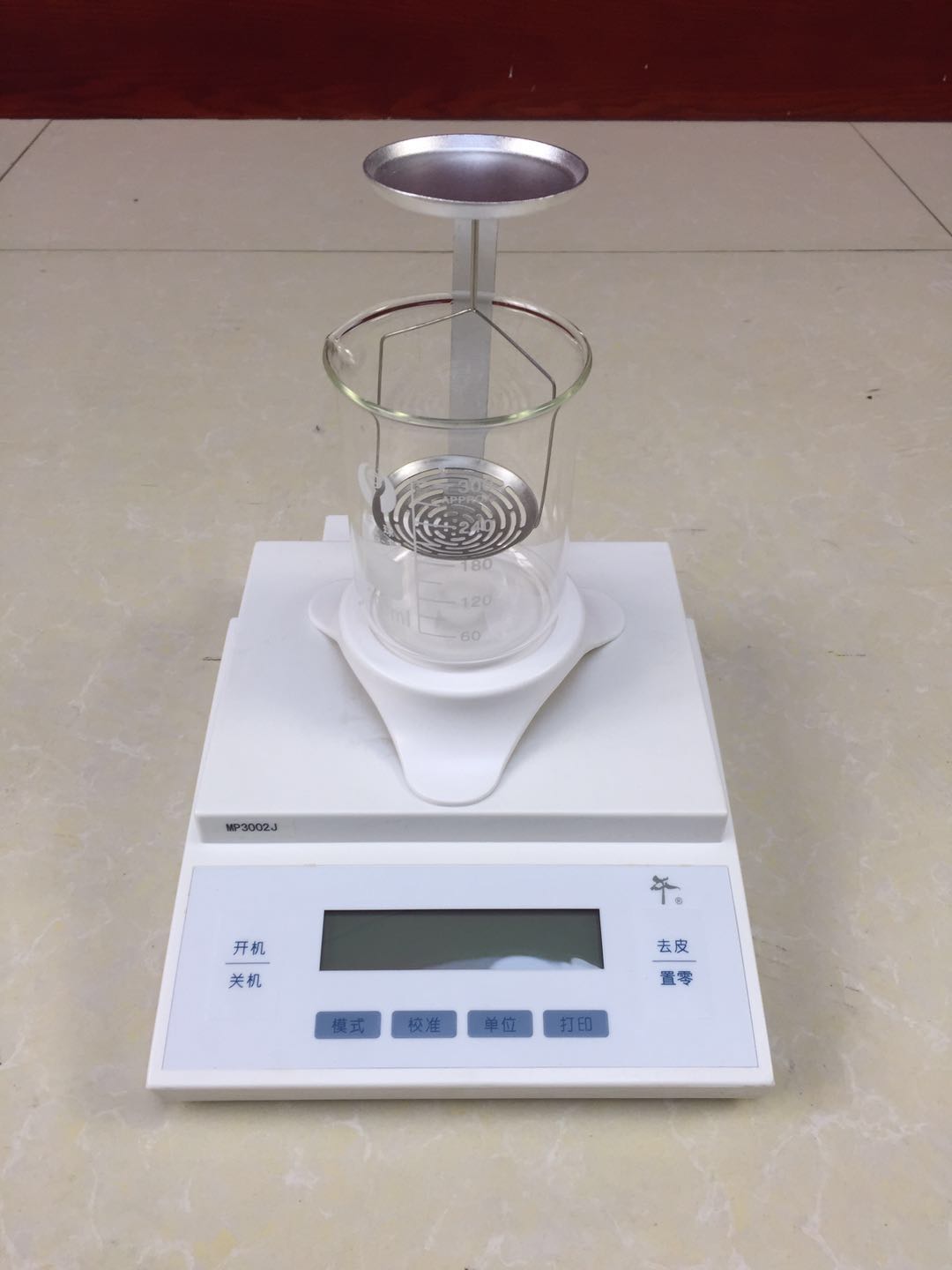

Manufacturers of cable bunched burning test machines are pivotal in providing the tools necessary for conducting these tests. These test machines are engineered with precision, incorporating advanced technologies to deliver accurate and reproducible results. They ensure that the testing process adheres to international standards such as ISO 9001, IEC 60332, and others, which are critical for manufacturers aiming to market their products globally.

The role of these manufacturers extends beyond merely supplying equipment; they are also instrumental in educating their clients. This involves training laboratory personnel on how to use the machinery effectively, understanding the parameters of the test, and interpreting the results correctly. As fire safety regulations continue to evolve, staying informed and compliant is a shared responsibility between the manufacturers and their clients.

Innovations in Testing Machinery

Modern cable bunched burning test machines reflect technological advancements in design and functionality

. Some of the innovations in this sector includecable bunched burning test machine manufacturers

1. Automated Systems Automation technology has transformed testing procedures, allowing for higher precision and reduced human error. Automated machines ensure consistent flame exposure and accurate timing, leading to more reliable results.

2. Real-time Monitoring Many contemporary machines come equipped with sensors and monitoring systems that provide real-time data on temperature, smoke density, and other critical variables. This capability enhances the safety of the testing process and results in more transparent data collection.

3. Modularity and Scalability To cater to various testing requirements, manufacturers are producing modular systems that can be adapted to specific testing needs. This scalability makes it easier for labs to conduct a range of tests without the need for multiple machines.

4. Environmentally Friendly Design Increasingly, manufacturers are focusing on sustainable production methods and materials in their machinery, aligning with global efforts to reduce environmental impact and promote safety.

The Market Landscape

The market for cable bunched burning test machine manufacturers has become increasingly competitive, with several companies vying for leadership in this specialized sector. Companies often differentiate themselves through innovation, customer service, and compliance with international safety standards.

As safety regulations tighten and the demand for high-quality, fire-resistant cables increases, the role of these manufacturers will continue to expand. Businesses involved in cable production are more inclined to invest in high-quality testing solutions, ensuring their products not only meet legal requirements but also provide genuine safety assurances to end-users.

Conclusion

In summary, cable bunched burning test machine manufacturers play an essential role in enhancing fire safety standards within the electrical industry. Their commitment to quality, innovation, and compliance with international standards helps ensure that the cables used in homes and businesses adhere to safety regulations that protect lives and property. As the market evolves and technology advances, these manufacturers will remain at the forefront of ensuring electrical safety, contributing to a more secure environment for all.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy