cable bunched burning test machine suppliers

Understanding Cable Bunched Burning Test Machines A Comprehensive Overview

In today's fast-paced electrical and telecommunications industries, the safety and reliability of cables are paramount. As a result, cable bunched burning test machines have become essential tools for manufacturers and testing laboratories. These machines are specifically designed to evaluate the fire performance of bundled cables, which are common in many applications, including homes, commercial buildings, and industrial facilities. This article explores the significance of cable bunched burning test machines, their functionality, and the suppliers in the market.

Importance of Cable Bunched Burning Tests

The primary purpose of conducting cable bunched burning tests is to assess the flammability and combustibility of cables when subjected to fire. Bundled cables can behave differently than individual cables during a fire; hence, testing them in groups is crucial for understanding their safety. With the rising concerns about fire hazards, regulatory bodies have implemented stringent standards that require comprehensive testing. By using these machines, manufacturers can ensure that their products meet safety regulations and minimize fire risks, ultimately protecting lives and property.

How Bunched Burning Test Machines Work

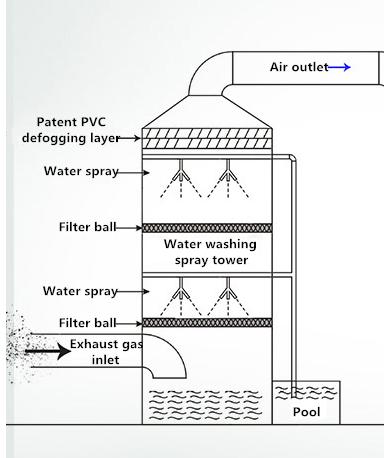

Cable bunched burning test machines simulate real-life fire conditions to observe how bundled cables respond to heat and flame. The testing process usually involves several steps

1. Sample Preparation Cables are arranged in a specified configuration to replicate typical installation scenarios. This configuration might include different types of cables bundled together.

2. Ignition Source An ignition source, often a flame or a hot coil, is applied to the bundle. The duration and intensity of the ignition can vary based on the standards being followed.

3. Measurement and Observation The machine measures critical parameters such as the time taken for flames to spread, the release of smoke and toxic gases, and the heat generated during combustion. These observations are crucial for determining the fire performance ratings of the cable bundles.

cable bunched burning test machine suppliers

4. Data Analysis Results are then analyzed to assess compliance with fire safety standards. Data collected from these tests help manufacturers predict performance in a fire scenario and refine their products accordingly.

Leading Suppliers in the Industry

As the demand for cable bunched burning test machines grows, numerous suppliers have emerged in the market, each offering unique features and capabilities. Some prominent suppliers include

- Comtest Engineering Renowned for its state-of-the-art testing equipment, Comtest Engineering provides a range of products designed to meet international safety standards. Their cable bunched burning test machines are equipped with advanced data acquisition systems for precise measurements.

- Lloyd Instruments Specializing in laboratory testing equipment, Lloyd Instruments offers machines that ensure reliable and consistent test results. Their equipment is designed for ease of use, allowing operators to conduct tests efficiently.

- Herzog Testing This supplier focuses on customized testing solutions, catering to specific client needs. Herzog’s machines are built for durability and can withstand rigorous testing environments while delivering accurate results.

- Babcock and Wilcox Known for its engineering excellence, Babcock and Wilcox offer sophisticated testing machines that come with comprehensive support services. Their commitment to safety makes them a trusted name in the industry.

Conclusion

The importance of cable bunched burning test machines cannot be overstated in an era where safety standards are continually evolving. These machines play a critical role in ensuring that bundled cables are reliable and safe for use in various applications. By partnering with reputable suppliers, manufacturers can enhance their research and development processes, leading to better products that stand up to the rigors of real-world fire scenarios. As technology advances, we can expect even more sophisticated machines that provide enhanced testing capabilities, further ensuring electrical safety in our communities.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy