cable bunched combustion test machine company

The Importance of Cable Bunched Combustion Test Machines in the Electrical Industry

In the ever-evolving landscape of electrical engineering, safety and reliability remain paramount. A crucial aspect of ensuring the integrity of electrical cables lies in the extensive testing they undergo. One specific type of testing apparatus that has gained significant attention is the cable bunched combustion test machine. This device plays a vital role in assessing the flame characteristics and combustion behavior of electrical cables when subjected to fire, making it indispensable for manufacturers and regulatory bodies alike.

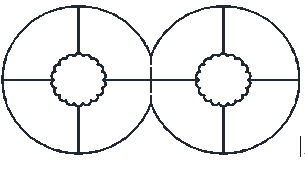

A cable bunched combustion test machine is designed to evaluate the performance of bundled cables under fire conditions. The device simulates real-world scenarios where cables, often grouped together, may experience exposure to an ignition source. The testing process typically involves placing a sample of bundled cables in the machine and subjecting them to various ignition sources to observe and measure the extent of combustion, flame spread, and potential toxic gas emissions.

One of the key reasons for the necessity of such testing machines is the stringent safety regulations imposed by national and international standards. Organizations such as Underwriters Laboratories (UL), the National Fire Protection Association (NFPA), and the International Electrotechnical Commission (IEC) have established comprehensive guidelines regarding the flammability of electrical materials. Manufacturers are required to ensure their products comply with these standards to minimize risks associated with electrical fires. The cable bunched combustion test machine facilitates compliance by providing reliable and reproducible data on flame behaviors.

cable bunched combustion test machine company

Moreover, as technology progresses, so does the complexity of electrical systems. Modern buildings utilize a myriad of bundled cables for power distribution, telecommunications, and data transmission. The risk of a fire instigated by electrical malfunctions necessitates thorough testing to predict how these cables will react in a crisis. The cable bunched combustion test machine assists engineers in identifying superior materials and designs that enhance fire resistance and overall safety.

In addition to safety, the use of cable bunched combustion test machines can significantly impact the longevity and performance of electrical cables. By determining flammability characteristics early in the design process, manufacturers can innovate and create products that not only meet regulatory requirements but exceed them. This proactive approach fosters consumer trust and satisfaction while also protecting the environment by reducing the likelihood of incidents that could lead to hazardous outcomes.

Furthermore, data gleaned from tests conducted with cable bunched combustion machines can serve as a benchmark for industry standards. As new materials and technologies enter the market, these machines provide essential insights that contribute to the evolution of testing protocols. Continuous improvement in testing methods lays the foundation for advanced research and development, pushing the frontier of safety in electrical engineering.

In summary, the cable bunched combustion test machine is a fundamental tool in the pursuit of fire safety and performance excellence in the electrical industry. It not only ensures compliance with rigorous safety regulations but also aids in the development of innovative materials and designs. As the reliance on complex electrical systems increases, the importance of thorough testing remains undiminished. Investing in sophisticated testing machinery like the cable bunched combustion test machine is an investment in safety, reliability, and the future of electrical engineering.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy