Cable Burning Test Equipment Producer for Reliable Performance and Safety Evaluation

Understanding Cable Burning Test Equipment A Manufacturer's Perspective

In today's world, where electrical systems proliferate across various industries, ensuring the safety and reliability of cables is paramount. Cable burning tests are a crucial part of the safety evaluation process for electrical cables, especially in commercial buildings and industrial settings. As an equipment manufacturer specializing in cable burning test equipment, our role is to provide reliable and innovative solutions that meet rigorous safety standards.

The Importance of Cable Burning Tests

Cable burning tests are designed to evaluate the fire performance of cables under defined conditions. These tests help in assessing how cables react when exposed to heat and flames, providing vital information about their combustion properties, flame spread characteristics, and the production of smoke and toxic gases. This data is essential for regulatory compliance, ensuring that cables meet the necessary fire safety requirements to protect lives and property.

In addition to regulatory compliance, cable burning tests are critical in the development phase of new cable products. Manufacturers can utilize test results to improve the fire resistance of their cables, enhancing their performance and market competitiveness. Hence, investing in high-quality cable burning test equipment is essential for manufacturers looking to innovate and ensure safety.

Features of Cable Burning Test Equipment

When it comes to cable burning test equipment, several key features make a significant difference in the quality and reliability of the tests conducted. First and foremost, precise temperature control is critical. Equipment should provide consistent heating rates and allow for accurate measurement of heat release, which is crucial in determining how a cable will react in a real-world fire scenario.

Moreover, the design of the test chamber is vital. It must facilitate proper airflow to replicate conditions typical of real fires while maintaining a controlled environment. Furthermore, the equipment should be capable of monitoring emissions, including smoke density and toxic gas levels, to provide a comprehensive understanding of the fire behavior of the cables.

cable burning test equipment manufacturer

Another important aspect to consider is user-friendliness. Modern equipment should incorporate digital interfaces and automation to simplify operations for test personnel. This user-centric design not only enhances efficiency but also helps in reducing human error during testing.

Our Commitment as Manufacturers

As a dedicated manufacturer of cable burning test equipment, we are committed to providing state-of-the-art solutions that adhere to international testing standards such as IEC, UL, and BS. Our team of engineers and safety experts collaborates closely with customers to understand their specific testing needs and ensure that our equipment meets or exceeds those requirements.

Additionally, we prioritize continuous innovation in our product development. The evolving landscape of materials and regulations necessitates equipment that can adapt to new challenges. By investing in research and development, we strive to create equipment that not only meets current performance standards but also anticipates future requirements.

Support and Services

Purchasing cable burning test equipment is just the beginning of a long-term partnership. We offer extensive support services, including installation, calibration, and ongoing maintenance, to ensure that our customers’ equipment remains in optimal condition. Furthermore, we provide training sessions for laboratory personnel to familiarize them with equipment operation and testing protocols, bolstering their confidence and expertise in conducting efficient tests.

Conclusion

In conclusion, cable burning test equipment plays a vital role in enhancing the safety and reliability of electrical cables. As a leading manufacturer, we are dedicated to designing and producing high-quality equipment that supports manufacturers in meeting stringent safety regulations. By prioritizing innovation, precision, and user support, we aim to contribute positively to the electrical industry’s safety landscape. Investing in cable burning test equipment is more than just compliance; it’s a commitment to safety, quality, and responsibility for all stakeholders involved.

-

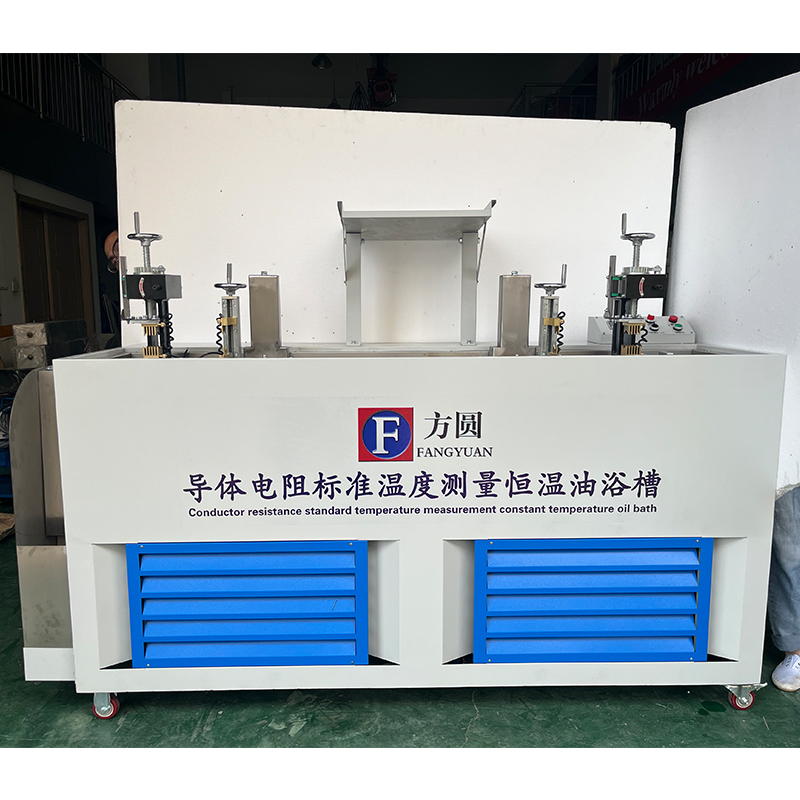

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy