cable combustion testing machine factories

The Importance of Cable Combustion Testing Machines in the Manufacturing Sector

In an era where safety and compliance are paramount, the cable industry faces heightened scrutiny regarding the performance and reliability of its products. Cable combustion testing machines play a critical role in ensuring that cables meet stringent safety standards before they reach the consumers. This article explores the significance of these machines, their operational principles, and their impact on manufacturing practices.

Overview of Cable Combustion Testing Machines

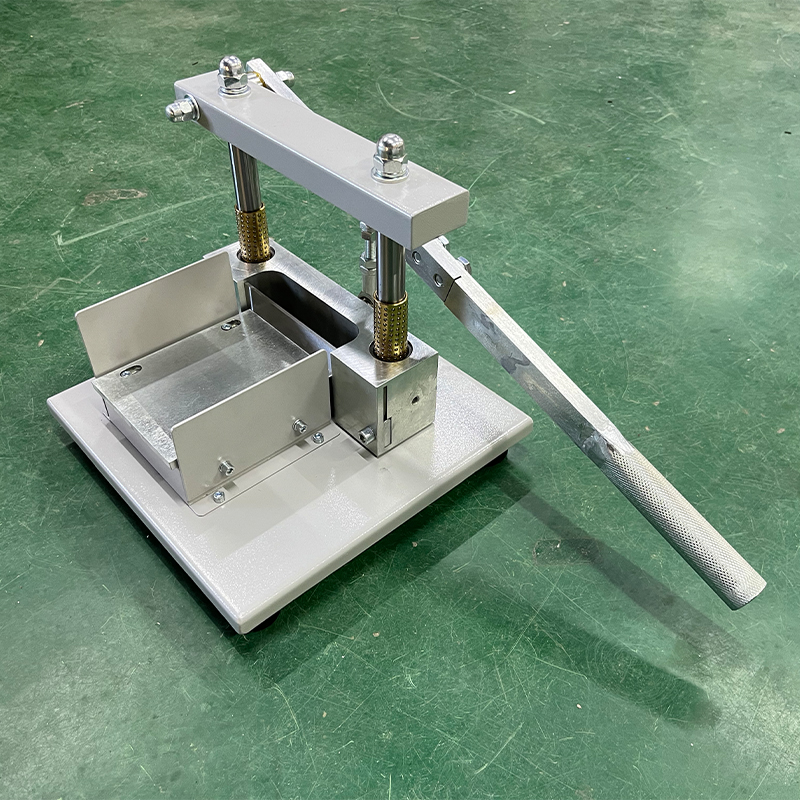

Cable combustion testing machines are specialized devices that evaluate the flammability and combustion characteristics of electrical cables. These tests are crucial as they simulate real-world scenarios in which electrical cables might be exposed to fire or high temperatures. The results from these tests help manufacturers to improve their products and comply with international safety standards, such as UL, IEC, and BS standards.

Operational Principles

The operation of a cable combustion testing machine involves several key processes. Typically, the machine assesses various parameters like ignition time, flame spread, smoke production, and the emission of harmful gases during combustion. The test begins with a sample cable being placed in a controlled environment where it is subjected to a specific heat source. The time it takes for the cable to ignite, the duration of the flame, and the extent of burn damage are meticulously measured and recorded.

Advanced combustion testing machines are equipped with sophisticated sensors and software that provide real-time data analytics. This technology allows manufacturers to monitor the performance of different materials and insulation types effectively. The results can be immediately analyzed, enabling rapid adjustments in product formulation and design.

Importance for Manufacturers

cable combustion testing machine factories

For manufacturers, cable combustion testing machines are indispensable. Firstly, they ensure compliance with regulatory standards, which is essential for market entry. Many regions require electrical cables to undergo rigorous testing before they can be sold. Non-compliance can result in substantial penalties or recall of products, which can damage a company's reputation and lead to financial losses.

Secondly, these machines help in product development. By understanding the combustion properties of various materials, manufacturers can innovate and create cables that are not only safer but also more efficient. This proactive approach to safety demonstrates a commitment to quality and consumer protection, which is increasingly important in today’s market.

Enhancing Safety Standards

The effectiveness of cable combustion testing machines extends beyond individual manufacturers. By ensuring that products meet safety standards, they collectively raise the bar for safety in the industry. This, in turn, protects consumers and reduces the likelihood of fire hazards caused by faulty or substandard electrical cables. Furthermore, as global demand for electrification increases, the need for stringent safety protocols becomes even more critical.

As safety standards evolve, so too must the capabilities of these testing machines. The latest advancements in technology are pushing the boundaries of what these machines can measure and analyze. For instance, incorporating machine learning algorithms and artificial intelligence can enhance predictive maintenance, enabling manufacturers to preemptively resolve potential combustion issues in cables.

Conclusion

In conclusion, cable combustion testing machines are vital components in the cable manufacturing process. Their ability to accurately assess the flammability characteristics of cables not only ensures compliance with safety regulations but also drives innovation and enhancements in product quality. As the industry continues to prioritize safety and efficiency, the role of these testing machines will become increasingly crucial.

Investing in modern cable combustion testing technology is an investment in safety, reliability, and the reputation of manufacturers. In a competitive market where consumer trust is paramount, providing high-quality, safe electrical products is essential. As such, cable combustion testing machines will continue to be indispensable in the quest for excellence in the cable manufacturing sector.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy