Cable Fire Test Equipment Manufacturer for Quality Assurance and Safety Standards

Cable Combustion Testing Machine Manufacturer Ensuring Safety and Compliance

In today’s rapidly evolving electrical industry, safety and compliance with international standards are paramount. One of the key components to achieving this is through rigorous testing of electrical cables. A Cable Combustion Testing Machine plays a crucial role in assessing the flammability and fire resistance of cables, helping manufacturers ensure that their products meet safety regulations. The growing awareness of fire hazards associated with electrical installations has led to an increased demand for specialized testing equipment, making cable combustion testing machine manufacturers essential players in the market.

Importance of Cable Combustion Testing

Cables are vital in almost every electrical system, from residential wiring to commercial and industrial applications. However, the materials used in cable insulation and sheathing can pose significant fire risks if they fail under certain conditions. Cable combustion testing machines are designed to evaluate how cables respond to flames and high temperatures, allowing manufacturers to determine their fire performance characteristics. This testing not only helps in meeting regulatory requirements but also protects end-users from potential hazards.

Various international standards, such as IEC 60332 and UL 1666, dictate the testing protocols that cable manufacturers must follow. These standards outline specific testing methodologies to evaluate aspects such as vertical flame propagation, smoke emissions, and toxic gas release. Consequently, manufacturers are increasingly investing in advanced testing machines that can deliver accurate and reliable results, ensuring compliance with national and international safety standards.

Features to Look for in a Cable Combustion Testing Machine

When selecting a cable combustion testing machine, several key features should be considered. Firstly, the machine should be capable of performing multiple tests in accordance with the relevant standards. This multi-functionality allows manufacturers to conduct various assessments, streamlining the testing process.

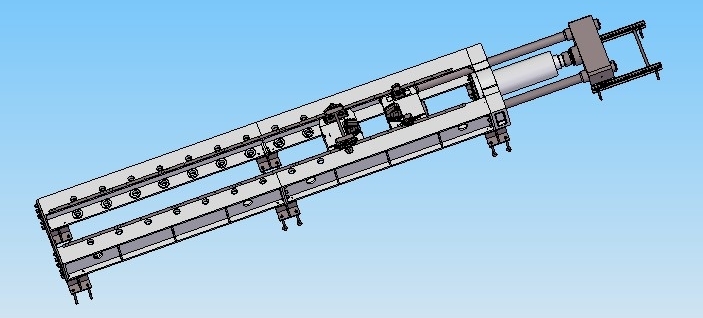

cable combustion testing machine manufacturer

Secondly, the machine should incorporate advanced technology for data collection and analysis. Modern machines often come equipped with digital interfaces, enabling real-time monitoring and easy documentation of test results. This feature not only enhances accuracy but also simplifies the reporting process, making it easier for manufacturers to track their compliance history.

Additionally, ease of use is a crucial factor. A user-friendly design can significantly reduce training time for operators and minimize the risk of errors during testing. Therefore, manufacturers should seek machines that offer intuitive controls and clear instructions.

The Role of Manufacturers

Manufacturers of cable combustion testing machines play a pivotal role in enhancing safety standards across the industry. They are responsible for continually innovating and improving their products, ensuring that they meet the changing needs of the market. This commitment to quality and technological advancement helps to establish trust with their clients.

Moreover, reputable manufacturers often provide comprehensive customer support, including installation, training, and maintenance services. This support is essential for ensuring that testing equipment operates at peak efficiency and produces reliable results over time.

Conclusion

As the demand for safe and compliant electrical systems continues to grow, the importance of cable combustion testing cannot be overstated. Manufacturers of cable combustion testing machines are at the forefront of this essential process, providing the technology that helps ensure the safety and reliability of electrical cables. By investing in state-of-the-art testing equipment, cable manufacturers can not only comply with regulations but also safeguard lives and property from fire hazards. As the industry evolves, these specialized manufacturers will continue to play a vital role in driving innovation and ensuring safety standards are upheld across the board.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy