cable cross-linked equipment suppliers

The Importance of Cross-Linked Equipment Suppliers in the Cable Industry

In today's rapidly evolving technological landscape, the role of cross-linked equipment suppliers in the cable industry has become increasingly vital. These suppliers specialize in providing essential materials and equipment that are fundamental to the manufacturing and distribution of cables, particularly those that require advanced durability and performance characteristics. This article delves into the significance of cross-linked equipment suppliers and the impact they have on the overall cable production process.

Understanding Cross-Linking

Before exploring the suppliers themselves, it is essential to understand the concept of cross-linking. Cross-linking refers to a method used in polymer chemistry where individual polymer chains are bonded together to form a three-dimensional network. This process significantly enhances the material’s strength, thermal stability, and chemical resistance. In the context of cable manufacturing, cross-linked polyethylene (XLPE) is a common material used for insulation and sheathing because of its superior performance compared to traditional materials.

The Role of Equipment Suppliers

Cross-linked equipment suppliers provide a range of products and services that are essential for the cable industry. These include

1. Raw Materials Suppliers provide high-quality raw materials such as cross-linked polymers, which are critical for producing durable cables. The quality of these materials directly affects the performance and longevity of the final product.

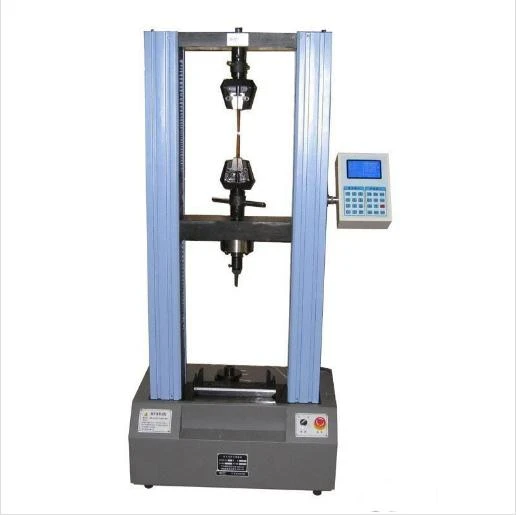

2. Manufacturing Equipment These suppliers also offer advanced machinery, including extruders and curing systems, specifically designed for the processing of cross-linked materials. The right equipment ensures that manufacturers can effectively produce cables that meet industry standards for performance and safety.

3. Technical Expertise In addition to supplying materials and equipment, many cross-linked equipment suppliers offer technical support and consultancy services. This expertise is invaluable for manufacturers who may be looking to optimize their production processes or troubleshoot specific challenges.

cable cross-linked equipment suppliers

4. Innovation and R&D Support As technology advances, so does the need for innovation in cable manufacturing. Suppliers often engage in research and development to create new materials and improve existing ones. This commitment to innovation is crucial for keeping pace with industry demands and standards.

Market Demand and Industry Growth

The demand for cross-linked equipment suppliers is on the rise, driven by several factors

- Increased Use of Renewable Energy The transition to renewable energy sources requires efficient and reliable cable systems. Cross-linked materials provide the necessary durability for installations in harsh environmental conditions.

- Urbanization and Infrastructure Development As urban areas continue to expand, there is a growing need for robust electrical and telecommunications infrastructure. Cross-linked cables are essential for these applications, providing the required performance for various installations.

- Technological Advancements The continuous evolution of technology in industries such as telecommunications, automotive, and construction further fuels the need for high-performance cables. Cross-linked equipment suppliers play a key role in meeting these evolving market needs.

Conclusion

In summary, cross-linked equipment suppliers are an indispensable component of the cable industry. Their provision of high-quality materials, specialized machinery, and technical expertise ensures that manufacturers can produce cables that meet the highest industry standards. As the demand for more advanced and resilient cable systems continues to grow, the role of these suppliers will become even more significant. Thus, investing in reliable and innovative cross-linked equipment suppliers is essential for any business looking to thrive in the competitive cable manufacturing landscape.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy