Leading Manufacturer of Crosslinking Equipment for Cable Production and Processing

Cable Crosslinking Equipment Manufacturer Paving the Way for Advanced Cable Technologies

In the rapidly advancing world of telecommunications and power distribution, the demand for high-performance cables is at an all-time high. One of the critical processes in producing these advanced cables is crosslinking. This essential technique enhances the physical and thermal properties of the cables, making them more durable and suitable for various demanding environments. As a result, the role of cable crosslinking equipment manufacturers has become increasingly significant in this evolving industry.

Understanding Cable Crosslinking

Crosslinking is a chemical process that creates a three-dimensional network between the polymer chains of the cable insulation materials. This network significantly improves the thermal stability, chemical resistance, and overall mechanical properties of the cables. The common materials subjected to crosslinking include polyethylene (PE), ethylene-vinyl acetate (EVA), and radiation-crosslinked compounds. Manufacturers utilize several technologies, including chemical crosslinking, electron beam (EB) crosslinking, and crosslinking using heat, each of which offers distinct advantages depending on the application.

The Role of Cable Crosslinking Equipment Manufacturers

Cable crosslinking equipment manufacturers specialize in designing and producing state-of-the-art machinery and systems that facilitate the precise and efficient crosslinking of cable materials. Their expertise encompasses various types of equipment, such as reactors, extruders, and irradiation systems. Each piece of equipment plays a vital role in ensuring the end product meets the stringent performance standards required in the industry.

1. Innovative Solutions These manufacturers are at the forefront of innovation, constantly improving their technology to enhance efficiency and output. For instance, the introduction of advanced control systems allows for better monitoring and adjustment of process parameters, resulting in higher quality products.

2. Customization With the diverse requirements of various industries—including telecommunications, energy, and automotive—cable crosslinking equipment manufacturers often provide customized solutions tailored to the specific needs of their clients. This flexibility helps manufacturers produce cables that meet unique specifications, including different thermal and mechanical properties, which can be crucial for applications in extreme conditions.

cable crosslinking equipment manufacturer

3. Sustainability Initiatives As the global focus shifts toward sustainability, many manufacturers are integrating environmentally friendly practices into their processes. This includes the use of less harmful chemicals in crosslinking operations and energy-efficient machines that reduce the overall carbon footprint of cable production.

4. After-sales Support and Service Good manufacturers understand that providing exceptional after-sales service is just as important as selling high-quality equipment. This includes training personnel, offering maintenance services, and providing ongoing technical support. Such services ensure that manufacturers can maintain high production rates and reduce downtime, which is vital for meeting market demands.

Challenges and Future Outlook

Despite the technological advancements, cable crosslinking equipment manufacturers face several challenges. These include the need to keep pace with rapidly changing technology, the demand for higher efficiency and lower costs, and the increasingly stringent regulatory requirements concerning environmental impact.

To address these challenges, manufacturers are investing in research and development, collaborating with industry stakeholders, and exploring new materials and processes. The future of cable crosslinking looks promising, with advancements in automation and smart technologies paving the way for more streamlined operations and further enhancements in cable performance.

Conclusion

In conclusion, cable crosslinking equipment manufacturers play a crucial role in the production of advanced cables that meet the diverse demands of modern applications. Through continuous innovation, customization, and a commitment to sustainability, these manufacturers are not only enhancing the quality of cables but are also shaping the future of the cable industry. Their contributions ensure that the world remains connected, safe, and efficient through the use of high-performance cables tailored to meet the challenges of today and tomorrow.

-

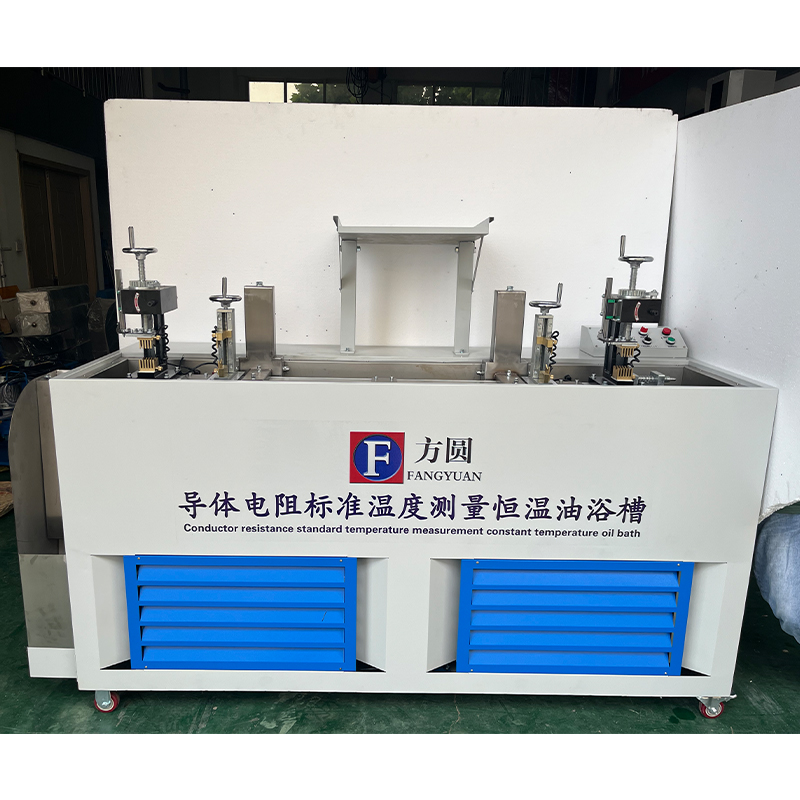

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy