Leading Manufacturers of Innovative Cable Crosslinking Machinery for Enhanced Production Efficiency

Understanding Cable Crosslinking Machine Manufacturers

In the realm of cable manufacturing, crosslinking plays a pivotal role in enhancing the performance and longevity of electrical and telecommunication cables. Cable crosslinking machines are essential for this process, providing the necessary technology to create cables that can withstand extreme temperatures, chemical exposure, and mechanical stress. As the demand for high-quality, durable cables continues to rise, the role of cable crosslinking machine manufacturers becomes increasingly significant.

The Importance of Crosslinking in Cable Production

Crosslinking is a chemical process that involves the formation of bonds between polymer chains, transforming them into a three-dimensional network. This process imparts enhanced properties to the cables, such as increased electrical insulation, improved thermal resistance, and greater flexibility, which are crucial for applications in various industries, including telecommunications, power distribution, and automotive.

To achieve effective crosslinking, manufacturers employ specialized machinery that can control factors such as temperature, pressure, and the concentration of crosslinking agents. This requires sophisticated engineering and design, making cable crosslinking machines complex yet indispensable components of the cable manufacturing process.

Types of Cable Crosslinking Machines

Cable crosslinking machines come in various forms, each serving different cable types and production scales. Among the most common types are

1. Dry Heat Crosslinking Machines These machines utilize high temperatures to enable the crosslinking reaction. This method is often used for polyethylene and PVC cables, as it provides an efficient means of creating robust and heat-resistant products.

2. Steam Crosslinking Machines This type uses steam as a medium to facilitate the curing process. It is particularly effective for crosslinking high-performance cables that require moisture exposure during manufacturing.

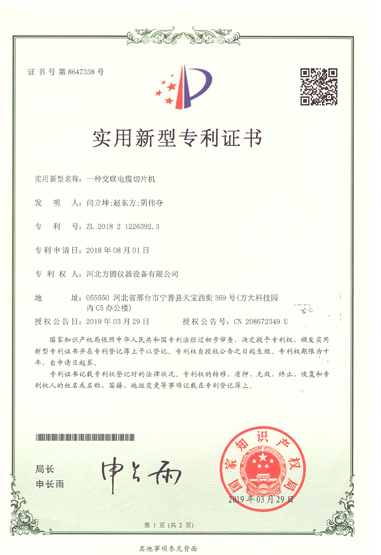

cable crosslinking machine manufacturers

4. Radiation Crosslinking Machines Utilizing electron beams or gamma radiation, these machines can perform crosslinking efficiently and are often favored for high-volume production due to their rapid processing times.

Leading Manufacturers in the Industry

The global market for cable crosslinking machines features several key manufacturers known for their innovative technologies and high-quality products. Companies like Siemens, Siemens, and Nexans are at the forefront, providing cutting-edge solutions tailored to the evolving needs of cable manufacturers.

These manufacturers focus on research and development to improve the efficiency and effectiveness of their machines. Features such as automation, enhanced safety protocols, and energy-saving technologies are becoming standard in advanced cable crosslinking machines. Moreover, many manufacturers offer customized solutions to cater to specific production requirements, further solidifying their position in the competitive landscape.

The Future of Cable Crosslinking Technology

As industries increasingly prioritize sustainability and efficiency, the future of cable crosslinking machines is likely to evolve. Manufacturers are investing in technologies that reduce energy consumption and minimize waste during the crosslinking process. Additionally, advancements in materials science may lead to the development of biodegradable or recyclable cables, necessitating modifications in existing crosslinking processes.

The rise of electric vehicles and renewable energy technologies is also expected to boost demand for specialized crosslinking machinery that can produce cables for specific applications. As the industry demands higher standards for performance and reliability, cable crosslinking machine manufacturers must stay ahead of technological trends to ensure they meet the needs of their clients.

Conclusion

The importance of cable crosslinking machine manufacturers cannot be undermined in today’s fast-paced industrial landscape. Their role in producing high-quality, durable cables is essential for various sectors, from telecommunications to renewable energy. As technology progresses, these manufacturers will play a critical part in shaping the future of cable manufacturing, ensuring that they continue to meet the evolving standards and demands of the market.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy