cable cutting machine factories

The Evolution and Importance of Cable Cutting Machine Factories

In the contemporary industrial landscape, cable cutting machines play an essential role in various manufacturing and construction processes. As industries evolve, so does the technology behind these machines, leading to an increase in dedicated factories that specialize in producing advanced cable cutting solutions. This article explores the significance of cable cutting machine factories, their technological advancements, and the impact they have on diverse sectors.

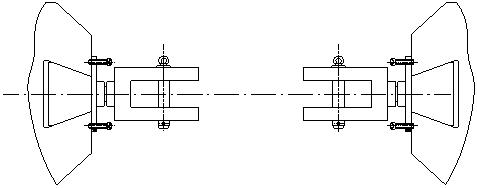

Cable cutting machines are designed to accurately and efficiently cut cables to desired lengths. They are crucial in industries such as telecommunications, electronics, automotive, and construction, where the precise handling of cables is vital. The importance of these machines cannot be overstated, as they directly influence production efficiency, reduce material waste, and enhance product quality.

The factories producing cable cutting machines have seen a remarkable transformation over the last few decades. Initially, these machines were relatively simple, primarily employing manual processes. However, with advancements in technology, manufacturers have integrated automation and computer numerical control (CNC) systems, allowing for more precise and faster operations. This evolution has enabled factories to cater to the increasing demand for customized cable lengths and specifications.

In today’s competitive market, flexibility and adaptability are key. Cable cutting machine factories have embraced this challenge by offering a range of models designed for different applications. Some machines are equipped with multi-functional capabilities, allowing them to cut various types of cables, from thick industrial wires to thin electronic leads. This versatility makes them indispensable tools in various production lines.

cable cutting machine factories

Moreover, environmental considerations have become increasingly important in manufacturing processes. Cable cutting machine factories are responding by adopting green technologies and sustainable practices. Modern machines are designed to minimize energy consumption and reduce waste. Factories implement recycling programs and focus on producing machines that generate less scrap material during the cutting process. This not only enhances their sustainability efforts but also reduces operational costs, making it a win-win situation for producers and the environment.

The global market for cable cutting machines has expanded significantly, driven by the proliferation of electronic gadgets and the increasing reliance on efficient communication systems. Countries around the world are investing in their manufacturing capabilities, leading to a surge in cable cutting machine factories. For instance, Asian countries, notably China and Japan, have become leaders in the production of these machines, utilizing advanced robotics and AI to streamline their operations.

Furthermore, the rising demand for high-quality cables in emerging industries such as renewable energy and electric vehicles has spurred innovation within cable cutting machine factories. Manufacturers are now focusing on refining their machines to accommodate the unique requirements of these sectors. For instance, machines that offer precision cutting for high-voltage cables are becoming crucial as the market shifts towards renewable energy sources.

As the industry progresses, the role of research and development cannot be overlooked. Cable cutting machine factories are investing heavily in R&D to stay ahead of technological advancements and market trends. Collaborations with local universities and research institutions are fostering innovation, resulting in the creation of next-generation machines equipped with smart technologies. These machines can analyze data in real-time, optimize cutting processes, and detect potential issues before they cause production delays.

In conclusion, cable cutting machine factories are at the forefront of manufacturing innovation, responding to the evolving needs of various industries. Their advancements in technology, focus on sustainability, and commitment to quality are not only enhancing production processes but also shaping the future of cable manufacturing. As industries continue to evolve, the importance of these factories will only grow, driving further innovations and setting new standards in the market. This makes cable cutting machine factories a pivotal component of industrial growth and technological advancement.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy