cable cutting machine manufacturers

The Rise of Cable Cutting Machine Manufacturers A New Era in Efficient Manufacturing

In an age where precision and efficiency are paramount in manufacturing, cable cutting machines have emerged as indispensable tools for various industries. The demand for these specialized machines has surged dramatically due to the rapid growth of sectors such as automotive, telecommunications, and electronics. Looking closely at the landscape of cable cutting machine manufacturers, we can understand how they are reshaping production processes and meeting the evolving needs of modern industry.

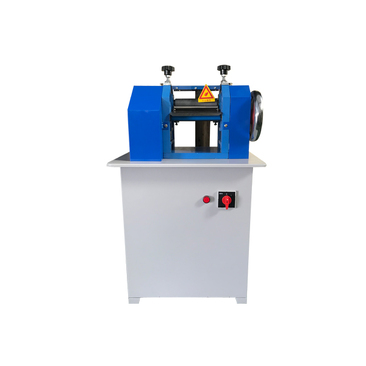

Cable cutting machines are engineered to deliver consistent and accurate cuts of different types of cables. These machines range from simple manual devices to sophisticated automated systems that use advanced technologies such as CNC (computer numerical control) and robotics. The benefits of using cable cutting machines are manifold – they enhance productivity, reduce waste, and significantly lower labor costs. As global competition intensifies, manufacturers are increasingly investing in these machines to gain a competitive edge.

One of the key factors driving the growth of cable cutting machine manufacturers is the increasing complexity of modern cables. With the proliferation of electrical equipment and devices, cables now come in various shapes, sizes, and materials. This diversity necessitates specialized cutting machines capable of handling multiple cable types while ensuring precision and quality. Manufacturers are responding to this challenge by innovating and developing versatile machines that can be easily adjusted to accommodate different specifications.

Moreover, the trend towards automation is another critical aspect impacting the cable cutting machine market. Automated systems not only streamline the cutting process but also integrate seamlessly with other production lines, creating an interconnected manufacturing environment. This transition to automation allows manufacturers to scale their operations and respond quickly to market demands. Companies that have adopted automated cable cutting machines report significant improvements in throughput and quality control.

cable cutting machine manufacturers

Environmental concerns are also shaping the cable cutting machine industry. Manufacturers are increasingly focusing on sustainable practices, including energy-efficient machines and processes that minimize waste. By designing machines that consume less power and generate less scrap material, manufacturers can address the environmental impact of production while also appealing to eco-conscious consumers.

Additionally, the rise of e-commerce has transformed how cable cutting machine manufacturers operate. Online platforms allow them to reach a global audience, making it easier for both small businesses and large manufacturers to procure cutting machines that best suit their needs. The accessibility of information via the internet enables companies to compare specifications, prices, and reviews before making purchasing decisions, fostering a more competitive market.

Customer service and support have also become crucial elements in the cable cutting machine business landscape. As manufacturers invest in more complex machinery, the need for training and technical assistance rises. Leading manufacturers are now offering comprehensive support packages, including installation, training, and ongoing maintenance services to ensure their clients can maximize the efficacy of their machines.

In conclusion, the landscape for cable cutting machine manufacturers is vibrant and evolving. With the increasing demand for precision in various industries, alongside the trends of automation and sustainability, manufacturers are poised to innovate continually. They are not just producing machines; they are driving the future of manufacturing. As industries continue to grow and change, the importance of high-quality cable cutting machines will only become more pronounced, marking a significant chapter in the story of modern manufacturing.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy