Mar . 06, 2025 13:56

Back to list

cable smoke density test machine company

In the bustling world of manufacturing, where precision and efficiency are paramount, cable cutting machine manufacturers and suppliers hold a significant place. An in-depth exploration of this niche reveals a blend of innovation, expertise, and a drive for perfection that defines the industry. This is not merely about machines—it's about the craftsmanship that engineers these high-performance tools to meet the demands of the modern market.

Trustworthiness is another pillar of this industry. It is cultivated through reliable customer support and robust after-sales services. Top-notch manufacturers stand by their products, offering training, maintenance, and quick resolutions to any operational issues. This is crucial, especially in time-sensitive production environments where downtime can lead to significant financial losses. A successful cable cutting machine manufacturer also keeps a close eye on market trends. Currently, there is a shift towards automation and smart manufacturing. Companies are integrating IoT (Internet of Things) and AI (Artificial Intelligence) into their machines, offering state-of-the-art solutions that lead to increased production efficiency and accuracy. Choosing the right supplier goes beyond assessing technical specifications; it's about establishing a relationship with a partner who understands the intricacies of your industry. Clients should seek manufacturers who not only supply equipment but also contribute to their operational goals through innovation, support, and continuous development. In summary, the cable cutting machine market is one of precision and progressive innovation. It requires a synthesis of experience, expertise, authority, and trust. Manufacturers and suppliers who excel in these areas not only provide high-quality machines but also enhance their reputation and maintain industry leadership. The decision to choose a manufacturer should be informed by these critical attributes, ensuring that your production is not just operational but optimized for success.

Trustworthiness is another pillar of this industry. It is cultivated through reliable customer support and robust after-sales services. Top-notch manufacturers stand by their products, offering training, maintenance, and quick resolutions to any operational issues. This is crucial, especially in time-sensitive production environments where downtime can lead to significant financial losses. A successful cable cutting machine manufacturer also keeps a close eye on market trends. Currently, there is a shift towards automation and smart manufacturing. Companies are integrating IoT (Internet of Things) and AI (Artificial Intelligence) into their machines, offering state-of-the-art solutions that lead to increased production efficiency and accuracy. Choosing the right supplier goes beyond assessing technical specifications; it's about establishing a relationship with a partner who understands the intricacies of your industry. Clients should seek manufacturers who not only supply equipment but also contribute to their operational goals through innovation, support, and continuous development. In summary, the cable cutting machine market is one of precision and progressive innovation. It requires a synthesis of experience, expertise, authority, and trust. Manufacturers and suppliers who excel in these areas not only provide high-quality machines but also enhance their reputation and maintain industry leadership. The decision to choose a manufacturer should be informed by these critical attributes, ensuring that your production is not just operational but optimized for success.

Latest news

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

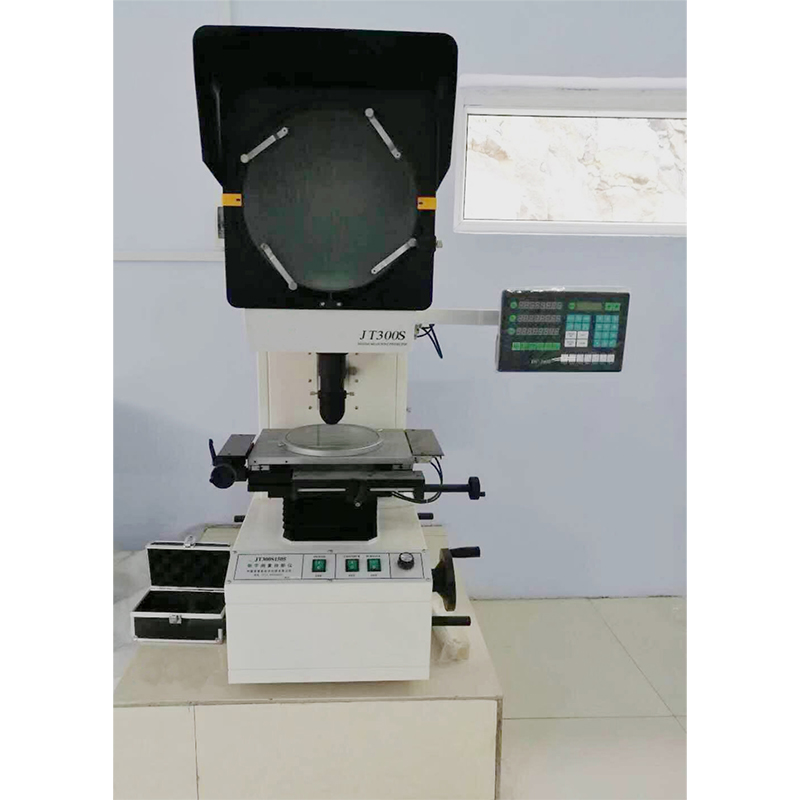

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy