Cable Fire Resistance Testing Equipment Manufacturer Solutions for Enhanced Safety Standards

Understanding Cable Fire Resistance Test Machines A Comprehensive Overview

In today’s world, safety is paramount, especially in industries where cables and wires are extensively used. With the increasing incidents of electrical fires, the importance of evaluating the fire resistance of cables has never been more vital. This is where the cable fire resistance test machine comes into play. This article delves into the significance, functionality, and manufacturing aspects of these machines.

The Importance of Fire Resistance Testing

Cables are the lifelines of electrical systems, and their failure can lead to disastrous outcomes, including fires that endanger lives and property. Fire resistance testing is essential to ensure that cables can withstand extreme temperatures and prevent fire spread. Regulatory bodies across the globe enforce stringent standards to ensure that cables used in buildings, vehicles, and other infrastructures are capable of withstanding fire conditions. Hence, the demand for machines that can efficiently conduct these tests has surged.

What is a Cable Fire Resistance Test Machine?

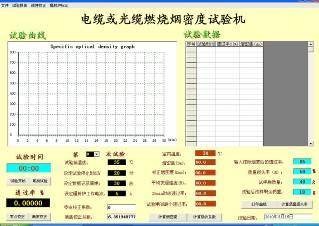

A cable fire resistance test machine is a specialized piece of equipment designed to evaluate the fire resistance properties of cables and wires. These machines simulate various fire scenarios, allowing manufacturers and researchers to observe how different types of cables respond under high heat and flame conditions. The results of these tests are critical in determining compliance with safety standards such as IEC, UL, and BS.

How Does the Machine Work?

The operation of a cable fire resistance test machine typically involves several stages

1. Preparation of Samples Cables to be tested are prepared according to specific dimensions and standards. This can involve cutting the cables to length and ensuring they are free from defects.

2. Test Setup The test machine is calibrated, and the sample cables are securely mounted. This ensures that the cables remain in place throughout the test.

cable fire resistance test machine factory

3. Ignition and Monitoring The machine ignites the test samples using controlled heat sources, often simulating real-world conditions. During this phase, the machine meticulously monitors various parameters including temperature, smoke production, and flame spread.

4. Data Logging Sophisticated data logging systems capture detailed information in real-time. This data is crucial for post-test analysis and for producing comprehensive reports that indicate the fire resistance characteristics of the tested cables.

5. Analysis and Reporting Once the tests are complete, the data is analyzed to determine whether the cables meet the necessary fire resistance standards. A detailed report is generated summarizing the test methods, results, and conclusions.

Manufacturing Aspects of Test Machines

The manufacturing process of cable fire resistance test machines involves advanced engineering and adherence to international quality standards. Key components often include

- Heat Sources High-quality burners or heating elements that can reach and maintain required temperatures. - Control Systems Computerized systems that manage test conditions, ensuring accurate and repeatable results. - Safety Features Robust safety mechanisms to protect operators from hazards associated with high temperatures and flames.

Reputable manufacturers of cable fire resistance test machines typically focus on innovation, durability, and user-friendliness. They invest in research and development to enhance the capabilities of their machines, incorporating features like automatic data analysis and integration with other testing devices for comprehensive evaluations.

Conclusion

As the demand for safer electrical infrastructure grows, so does the necessity for reliable and accurate cable fire resistance testing. Cable fire resistance test machines play a crucial role in this regard, allowing manufacturers to produce safe and compliant products. With continued advancements in technology, these machines will undoubtedly evolve, further enhancing their efficacy and reliability. By investing in quality testing equipment, businesses not only protect their consumers but also contribute to a safer environment for all.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy