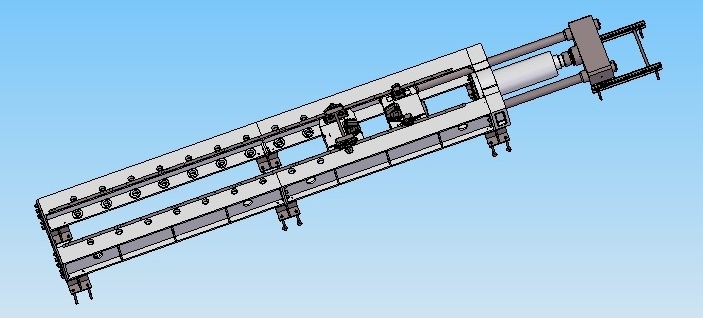

cable flexibility test machine exporter

The Importance of Cable Flexibility Test Machines in Modern Industry

In today's technologically driven world, the integrity and reliability of electrical cables are paramount. As industries continue to push the boundaries of innovation, the demand for high-performing cables has never been higher. Among the numerous tests conducted on cables, the cable flexibility test stands out as a critical evaluation of a cable's durability and suitability for various applications. This has led to a surge in manufacturers specializing in cable flexibility test machines, which are crucial for ensuring cable quality and compliance with international standards.

Understanding Cable Flexibility Testing

Cable flexibility testing assesses a cable's ability to withstand bending and flexing without sustaining damage or performance loss. Cables are often subjected to various mechanical stresses during installation and usage. The flexibility test simulates these real-world conditions, allowing engineers and quality assurance teams to identify potential points of failure before the product reaches the market.

The process typically involves bending the cable at specified angles and for a predetermined number of cycles. High-quality flexibility test machines can measure the mechanical properties of cables, including tensile strength, elongation, and resistance to fatigue. This information helps manufacturers alter their designs or materials to enhance performance.

The Role of Cable Flexibility Test Machine Exporters

Cable flexibility test machine exporters play a vital role in the global supply chain for cable manufacturing. They provide manufacturers with state-of-the-art testing equipment designed to deliver accurate results quickly. With the increasing complexity of cable designs, including multi-core cables, shielded cables, and various insulation types, the need for advanced testing technology is crucial.

Exporters offer a range of testing machines, from basic models to sophisticated setups equipped with computer interfaces for data analysis and reporting. Investing in high-quality equipment not only improves testing efficiency but also ensures compliance with industry regulations and standards, such as ISO and IEC specifications.

Key Features of High-Quality Cable Flexibility Test Machines

cable flexibility test machine exporter

1. Automation Modern machines come with automated features that streamline the testing process. This reduces the risk of human error and allows for consistent results across multiple tests.

2. Data Logging Advanced machines can log and store test data for analysis. This feature is essential for monitoring trends over time and ensuring that manufacturers can trace any variations in their production lines.

3. Customizability Different cables have different testing requirements. Leading exporters provide customizable machines tailored to specific cable types or testing conditions, enabling manufacturers to meet unique project specifications.

4. User-Friendly Interfaces Many newer models feature intuitive software that allows operators to easily navigate through different test settings and parameters. This reduces training time and enhances productivity.

5. Durability and Maintenance Quality exporters ensure that their machines are built to last, incorporating high-quality materials that can withstand the rigors of testing. Additionally, regular maintenance support is a hallmark of reputable exporters, ensuring longevity and reliability.

Conclusion

As the demand for robust and reliable cables continues to rise, the role of cable flexibility test machine exporters becomes increasingly vital. By providing advanced testing solutions, these exporters contribute to the overall quality and safety of electrical systems across industries.

Investing in top-tier cable flexibility test machines helps manufacturers not only comply with international standards but also enhances their reputation in the market. With technology constantly evolving, staying ahead in cable testing capability is essential. Consequently, manufacturers who embrace quality testing practices will not only improve their products but also gain a competitive edge in an ever-changing landscape.

In summary, the importance of cable flexibility testing cannot be overstated, and the exporters of testing machines are pivotal in fostering innovation and excellence in cable manufacturing. By ensuring that cables can endure the demands of modern applications, these machines help pave the way for safer, more efficient electrical systems worldwide.

-

Why the Conductor Resistance Constant Temperature Measurement Machine Redefines Precision

NewsJun.20,2025

-

Reliable Testing Starts Here: Why the High Insulation Resistance Measuring Instrument Is a Must-Have

NewsJun.20,2025

-

Flexible Cable Flexing Test Equipment: The Precision Standard for Cable Durability and Performance Testing

NewsJun.20,2025

-

Digital Measurement Projector: Precision Visualization for Modern Manufacturing

NewsJun.20,2025

-

Computer Control Electronic Tensile Tester: Precision and Power for the Modern Metal Industry

NewsJun.20,2025

-

Cable Spark Tester: Your Ultimate Insulation Assurance for Wire and Cable Testing

NewsJun.20,2025

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy

Copyright © 2025 Hebei Fangyuan Instrument & Equipment Co.,Ltd. All Rights Reserved. Sitemap | Privacy Policy